You’re currently viewing the Australia website.

You’re currently viewing the Australia website.

Would you like to switch countries or language?Blast Abrasives

Topics

Waterjet Cutting

Topics

Resources

Categories

Types

Categories

Topics

Abrasive Blasting eBook silica English Australia

Understanding Australia's Silica Limits in Abrasive Blasting

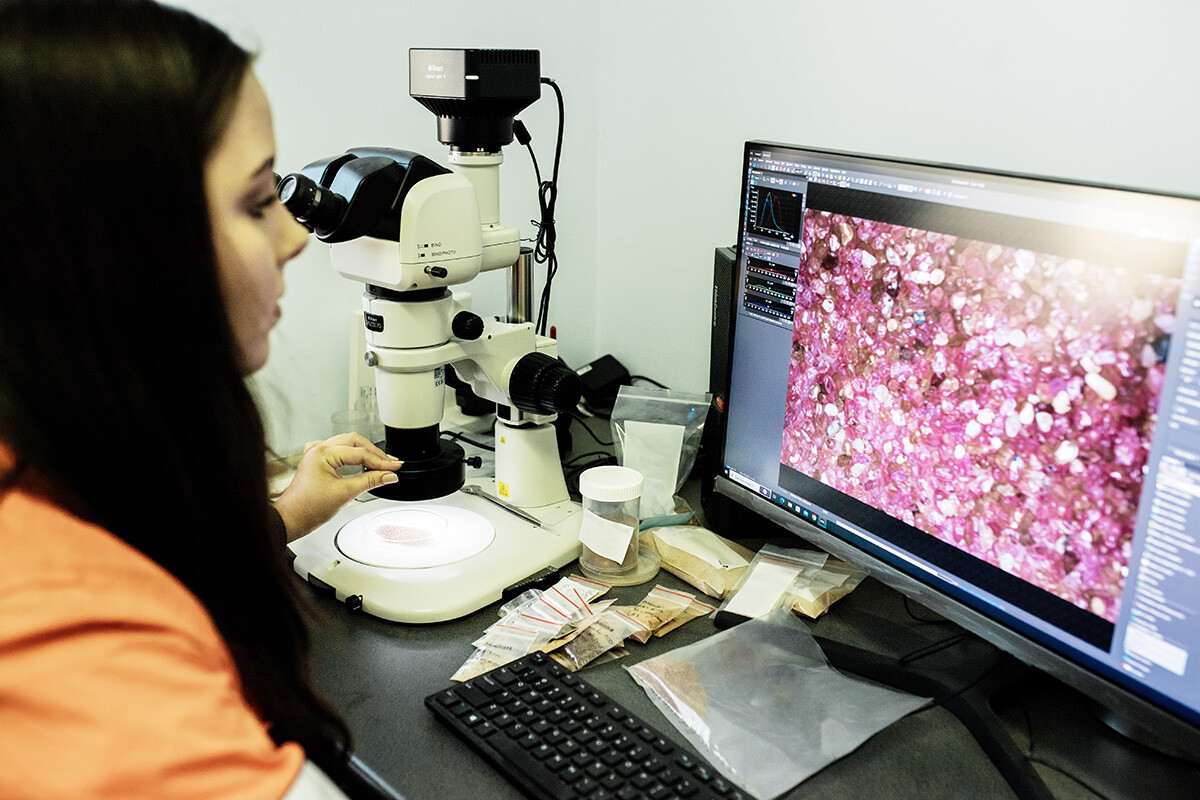

The quality levels of garnet depend on the deposit, mining, and processing controls in place. Understand what is in the bag, and what it means to your abrasive blasting operations.

This discussion paper aims to help inspectors, safety and environmental professionals understand silica, free silica, what is in a bag of GMA Garnet™, and what it means to abrasive blasting operations.

Read the full report

What is crystalline silica?

Silica is a natural mineral called silicon dioxide, found in abundance in rocks, sands, and soils. It exists in both non-crystalline and crystalline forms, with quartz being the most common crystalline form. The presence of silica varies greatly in different rocks and rock products, and it is a component of materials like mortar, concrete, and mineral sands.

Free crystalline silica and GMA Garnet™

The quality levels of garnet vary based on where they come from, how they are mined, and processed. GMA Garnet™ comes from ancient rock, made into pure almandine garnet through world-class mining and processing that removes most impurities. Rigorous testing is conducted multiple times a day to ensure high garnet purity and concentration levels. Independent third party tests are also conducted regularly to determine low levels of free crystalline silica and readily available upon customer’s request. GMA’s free crystalline silica results come well under the minimum threshold

of 1% of weight by volume (usually under 0.1%)

Consistent quality that performs.

GMA Garnet™ is not only intrinsically safe to use, its consistent sizing and quality produce reliable abrasive blasting performance every time. It's rigorously tested in 12 key areas to meet top industry and safety standards.

GMA ToughBlast™

GMA ToughBlast™ GMA PremiumBlast™

GMA PremiumBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ClassicCut™ 60

GMA ClassicCut™ 60 GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile