You’re currently viewing the Global website.

You’re currently viewing the Global website.

Would you like to switch countries or language?Blast Abrasives

Waterjet Cutting

Topics

Resources

Categories

Types

Categories

Topics

Abrasive Blasting Tech Tips English Global

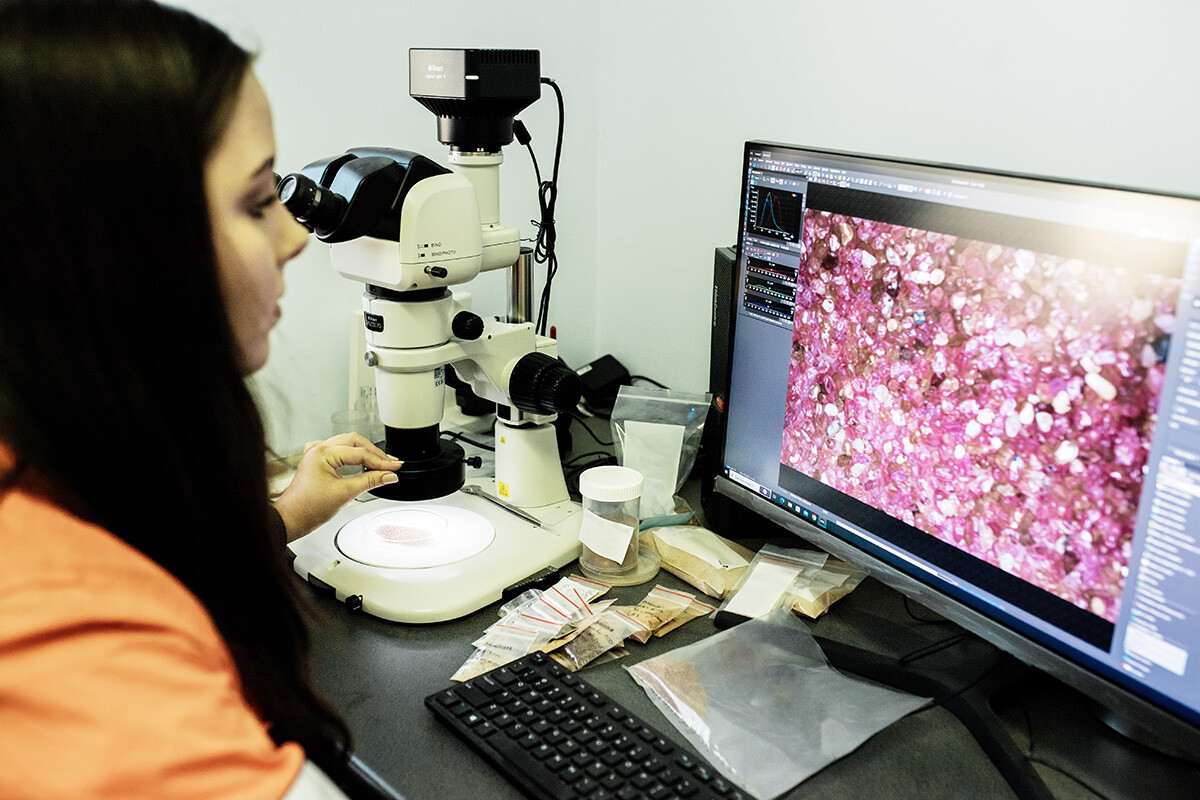

Understanding Abrasive Media and Their Properties

Abrasive blasting, often referred to as sandblasting, is a process that involves propelling a stream of abrasive material against a surface under high pressure. This technique is used to smooth rough surfaces, roughen smooth surfaces, shape surfaces, or remove surface contaminants. It is a versatile and efficient method employed in various industries, including construction, manufacturing, and shipbuilding.

Types of Blast Abrasive Media

There are various types of blast abrasive media, each with its unique properties and applications:

- Garnet: Known for its superior hardness and toughness, garnet is one of the most effective and efficient abrasive media. It offers excellent cutting speed, low dust emissions, and recyclability. Garnet is particularly valued for its ability to produce a high-quality finish and its suitability for a wide range of applications, including surface preparation and waterjet cutting.

- Crushed Glass: This media is effective for surface cleaning and is often used to remove paint, rust, and other contaminants. Crushed glass is environmentally friendly as it is made from recycled materials, and it provides a good balance between cost and performance.

- Staurolite: A mineral abrasive that is less aggressive than garnet but still effective for various blasting applications. Staurolite is known for its lower dust levels and moderate cutting speed, making it suitable for delicate surfaces.

- Steel Shot: Ideal for peening and cleaning metal surfaces, steel shot is a highly durable abrasive that can be reused multiple times. It provides a smooth, polished finish and is often used in automotive and aerospace industries.

- Slag: A byproduct of metal smelting, slag is commonly used in industrial applications. It is cost-effective and suitable for aggressive blasting tasks, but it tends to generate more dust and is less environmentally friendly compared to other abrasives.

- Plastic: Used for delicate surfaces where metal abrasives would be too harsh, plastic media is ideal for applications that require a gentle touch, such as aerospace and electronics cleaning.

Four Critical Abrasive Characteristics

To choose the right abrasive media, it's essential to understand four critical characteristics:

- Hardness: The ability to create a deeper impact. Harder abrasives can penetrate tough coatings more effectively. Garnet, for example, has a higher relative hardness, which makes it more effective for creating a consistent anchor profile.

- Density: Denser abrasives create a deeper, more consistent profile. Heavier materials like garnet are particularly effective in this regard, as they can deliver more energy to the surface being blasted.

- Toughness: Resistance to fracturing upon impact. Tough abrasives like garnet are more durable and can be recycled multiple times, reducing overall material costs.

- Angularity: Affects how deep the grain cuts into the surface. Angular grains produce sharper profiles, which are ideal for creating a rough surface that coatings can adhere to, while rounded grains produce smoother profiles.

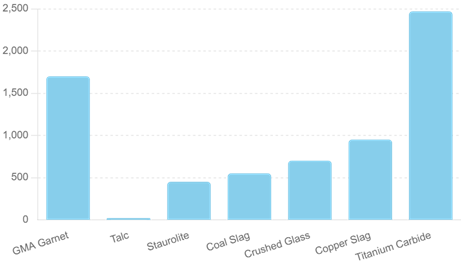

Hardness Comparison

Using the Knoop scale, we can compare the hardness of various materials:

Knoop Hardness of Various Abrasive Materials

Y Knoop Hardness by X Abrasive Material

Understanding these properties helps in selecting the right abrasive for specific applications, ensuring efficiency and effectiveness. Garnet's unique combination of hardness, density, toughness, and angularity makes it an outstanding choice for a wide range of blasting tasks, providing both high performance and environmental benefits.

Selecting the appropriate abrasive media is crucial for achieving optimal results in abrasive blasting. By considering factors such as hardness, density, toughness, and angularity, and understanding the specific properties and applications of different media types, you can ensure that your blasting operations are both efficient and effective. GMA Garnet™ stands out as the preferred industry choice, offering exceptional performance and sustainability advantages.

GMA ToughBlast™

GMA ToughBlast™ GMA PremiumBlast™

GMA PremiumBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ClassicCut™ 60

GMA ClassicCut™ 60 GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile