Infrastructure

GMA Garnet™ provides a range of high-performance garnet abrasives for civil and commercial infrastructure, delivering proven benefits and improvements in abrasive productivity and performance.

Get a cleaner surface faster, with minimized OSH risks

Approved by paint and coating manufacturers around the world, GMA Garnet™ is the preferred garnet abrasive of major industrial fabricators, builders and commercial contractors. From commercial buildings and plant facilities to stadiums and bridges, GMA is a global leader in abrasives that provide proven efficiency gains.

High productivity

Achieve your specified surface profile faster than alternate abrasives.

Low consumption

Complete the job with far less abrasive, reducing costs in abrasive purchase, transport, and disposal.

High peak density

Generate higher peak density over alternate abrasives for unmatched coating adhesion and integrity.

Low embedment

60% of the average slag-blasted surface is embedded with residual abrasive. Garnet results in minimal embedment.

Low dust

GMA Garnet™ offers the closest thing to dustless blasting, drastically improving operator visibility and reducing site contamination.

Low safety risk

Garnet is an inert mineral with little to no heavy metals creating worker risks or environmental hazards.

Twice the productivity with less than half the abrasive consumption

When Heinrich Schmid took on the maintenance work for the Salier Bridge in Speyer, Germany, they were seeking a faster performing, and less dusty abrasive.

Commercial Structural Steel, Stadiums & Venues

- In fabrication of structural steel GMA NewSteel™ is the fastest abrasive available for removing hard mill scale.

- Creates the required surface profile with consistent peak density, far higher than alternate abrasives (3-5 times higher than slags) for stronger coating adhesion

- Exceptional surface cleanliness with minimal abrasive embedment for better corrosion resistance and substrate integrity

- With the right equipment GMA Garnet™ can provide a high level of reusability through recycling onsite

- Inert, sustainable natural mineral, with little to no recordable heavy metals and worker hazard risks

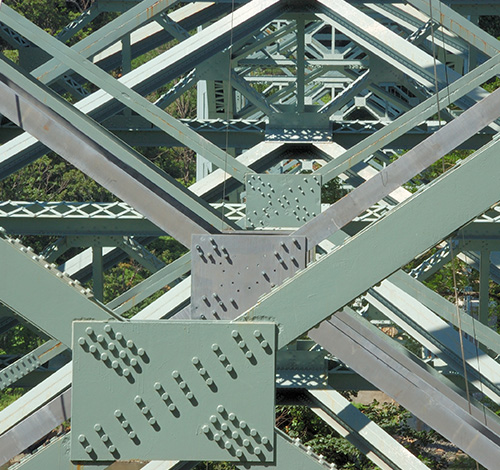

Bridges

- Very low dust emissions, improving visibility and productivity particularly in confined spaces

- High blasting and cleaning efficiency, leading to lower abrasive consumption, and lower clean-up and disposal costs than waste slags

- Creating the required surface profile with consistent peak density for stronger coating adhesion

- Exceptional surface cleanliness with minimal abrasive embedment for better corrosion resistance and substrate integrity

- Inert, sustainable natural mineral, with little to no recordable heavy metals, reducing worker risks and hazards, and environmental contamination

Water & Wastewater Storage and Treatment

- Very low dust emissions, improving visibility and productivity particularly in confined spaces

- High blasting and cleaning efficiency, leading to lower abrasive consumption, and lower clean-up and disposal costs

- Creating the required surface profile with consistent peak density for stronger coating adhesion

- Exceptional surface cleanliness with minimal abrasive embedment for better corrosion resistance and substrate integrity

- Inert natural mineral, with little to no heavy metals reducing the potential of environmental contamination - The safest abrasive to lower risk in residential areas and for workers.

Related content

Safely create clean, consistent surfaces

Find out how GMA can produce the range of surface profiles that your protective coatings require — safely, efficiently, and without disrupting your facility.

GMA ToughBlast™

GMA ToughBlast™ GMA PremiumBlast™

GMA PremiumBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ClassicCut™ 60

GMA ClassicCut™ 60 GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile