Global pioneers in garnet abrasives

We started our journey towards commercializing garnet as a natural industrial abrasive in the 1970’s. Today, GMA Garnet™ is used in over 100 countries worldwide.

Global pioneers in garnet abrasives

We started our journey towards commercializing garnet as a natural industrial abrasive in the 1970’s. Today, GMA Garnet™ is used in over 100 countries worldwide.

From unused mineral to global industry standard

GMA Garnet™ originated in Western Australia where our primary source of garnet was discovered near the coastal town of Port Gregory. There resides the world's largest and most concentrated alluvial garnet resource.

Yet garnet wasn’t always recognized as the high-performance abrasive it is today. At the time of discovery, garnet was dismissed as a low-value mineral with no known uses or applications. It took an innovative team to take on the challenge of finding its possibilities, receiving positive responses from the local abrasive blasting industry.

During the decades that followed, GMA identified high-grade garnet deposits, secured new tenements, and developed processing and recycling plants in regions around the world. We continued to develop the use of garnet in both surface preparation and the waterjet cutting industry, and engineered new garnet blends for high-performance results. That dedication remains unchanged today.

GMA Garnet Group’s success has been solidified through the pursuit of innovation, performance, reliability, and sustainability in every aspect of our global business. Here’s how we paved the way in industrial garnet.

The history behind the world’s best garnet

1971

What became known as GMA Garnet Group established

Target Minerals pegged several mining tenements for mineral sands along the coast of Western Australia (WA). A small pilot plant was established in 1974, though it took a number of years for the venture to take hold.

1973-74

First sampling carried out identifying garnet in low concentration (by Martin Taylor who joined Target Minerals in late 1971). A detailed sampling program in 1973/1974 indicated nearly 3 million tonnes of high grade garnet to be available.

1976-78

Garnet sales commenced in 1976, initially totaling 228 metric tons sold to the local market to end 1977. A small scale wet processing plant was set up the following year in Northampton, WA, AU, while contract dry processing continued further south in Perth.

1981

GMA won several major contract orders, paving the way for the new wet processing facilities at Port Gregory and a dry processing plant in a rented facility in Geraldton, WA, AU.

One of those contracts included the supply of over 2,000 metric tons of garnet for use in the construction of the 1,600 km Dampier to Bunbury Natural Gas Pipeline (DBNGP).

.jpg?width=270&height=230&name=Rectangle%20707%20(1).jpg)

1983

.jpg?width=270&height=230&name=Rectangle%20707%20(1).jpg)

1983 is considered GMA’s founding year, when a small production facility and marketing of industrial garnet started to take hold globally.

The DBNGP project was a turning point for GMA, as the use of garnet as an high-performance abrasive was quickly recognised globally and allowed GMA to enter new markets: Asia, the Middle East, Europe, and America.

A dry processing plant was established at Narngulu, Geraldton. Container shipments to Europe and the Middle East commenced.

1988

The Narngulu dry plant built in 1983 had been upgraded several times to keep up with sales demand for garnet sand. The success of this plant was partly due to the early introduction of rare earth drum magnets (GMA was one of the pioneers to use them in the mineral sands industry) and innovative use of screening equipment.

.jpg?width=270&height=230&name=Rectangle%20707%20(2).jpg)

1993

.jpg?width=270&height=230&name=Rectangle%20707%20(2).jpg)

The operating company name was changed to GMA Garnet Pty Ltd. Previously Garnet Millers Associates Pty Ltd and Garnet Producers NL, Target Minerals NL.

.jpg?width=270&height=230&name=Rectangle%20707%20(3).jpg)

1996

.jpg?width=270&height=230&name=Rectangle%20707%20(3).jpg)

First shipments of GMA’s Ilmenite made to Japan and commencement of ilmenite by-product production and sales commenced.

1997

The wet and dry processing plants were upgraded in 1997 to handle over 300,000 metric tons of garnet production annually. A ‘hose’ wet plant was also commissioned the following year with name-plate production capacity of 225,000 metric tons.

Our operations.jpg?width=270&height=230&name=Rectangle%20707%20(4).jpg)

1999

.jpg?width=270&height=230&name=Rectangle%20707%20(4).jpg)

GMA Garnet Middle East was established with a bulk handling and packaging plant in the Jebel Ali Free Zone, Dubai.

2001

Foundation of GMA Garnet Group: Garnet International Resources Pty Ltd(GIRL) is established in Perth by the partners T Ketelsen, HM Jebsen, J.H. Jessen , W Puzier, Torsten Ketelsen appointed Managing Director & CEO.

2002

Garnet International Resources Pty Ltd was formed, with Torsten Ketelsen, Wolfhart Putzier, Hans Michael Jebsen & Heinrich Jessen as Shareholders, to acquire 50% of GMA Garnet Pty Ltd (from Hancock & Gore), the owner of the Port Gregory Mine and Midwest operations. This was the first step in combining mining & processing, with the sales & distribution businesses to create a vertically integrated global garnet business.

2003

Jebel Ali waste management recycling plant established in the United Arab Emirates in the Jebel Ali free zone.

2004

By 2004 the production of value-added grits and powders for the traditional abrasives market, part of the original plan, had been discontinued due to reduced demand caused by changing technology and increased competition from other suppliers.

The blast abrasive market was the driving force behind GMA’s success, but by the early 2000’s, Waterjet cutting was an emerging major market.

.jpg?width=270&height=230&name=Rectangle%20707%20(5).jpg)

2005

.jpg?width=270&height=230&name=Rectangle%20707%20(5).jpg)

2005 saw investment in garnet sustainability with the establishment of Garnet Arabia Company WLL, a joint venture between the Group and Global Suhaimi, in addition to a reprocessing plant in Saudi Arabia.

GMA Group establishes a Garnet Reprocessing Plant in Italy to process used waterjet garnet.

GMA gained a foothold in the Americas by establishing GMA Garnet USA in Houston, Texas with loose bulk handling plants and warehouses throughout North America.

Sustainability at GMA2006

GMA Garnet Group was runner-up to Rio Tinto for WA Exporter of the Year in the Minerals & Energy category.

2007

GMA Group won the 2007 West Australian Industry & Export Awards in the Minerals & Energy category.

GMA Group won the 2007 Australian Export Awards in the Minerals & Energy category.

.jpg?width=270&height=230&name=Rectangle%20707%20(6).jpg)

2009

.jpg?width=270&height=230&name=Rectangle%20707%20(6).jpg)

GMA Americas opened a recycling, bulk handling, and packaging plant near New Orleans, Louisiana, USA.

.jpg?width=270&height=230&name=Rectangle%20707%20(7).jpg)

2010

.jpg?width=270&height=230&name=Rectangle%20707%20(7).jpg)

Garnet Reprocessing & Recycling Plant in Italy was relocated to a new site in Aulla-Pallerone and the facility was upgraded with state-of-the-art drying, processing, screening, and packaging technology and equipment.

2011

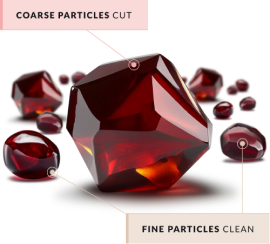

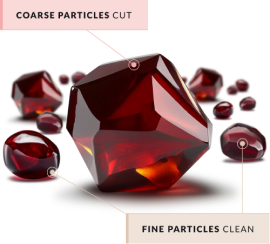

The Next Generation abrasives range started taking shape in 2011 with the significant development of engineered blends for the blast abrasives market. Engineered blends, a non-conforming grade, had a wider distribution of both cutting and cleaning grain sizes.

GMA’s engineered range of ‘cut and clean’ to produce a fast cutting performance with a cleaner surface. This was a big innovation and divergence from traditional one-dimensional abrasive sizing.

GMA also opened a bulk handling and packaging plant in Pennsylvania, USA. Back in Geraldton, a record-breaking two million metric ton of GMA Garnet™ was shipped through port to date.

.jpg?width=270&height=230&name=Rectangle%20707%20(8).jpg)

2014

.jpg?width=270&height=230&name=Rectangle%20707%20(8).jpg)

An offtake agreement for garnet concentrate from MRC (ASX:MRC), South Africa commences.

GMA acquires 2/3rd ownership of GUSA Hardrock garnet mine operations in Montana, USA.

2016

Extensive investment in exploration and drilling results from the adjoining exploration area in Port Gregory extend GMA’s garnet reserves to potentially increase life of mine to over 25 years from 2016.

.jpg?width=270&height=230&name=Rectangle%20707%20(9).jpg)

2017

.jpg?width=270&height=230&name=Rectangle%20707%20(9).jpg)

Fairless Hills, Pennsylvania processing plant was officially opened. At the time Fairless Hills was our most innovative plant capable of processing garnet concentrate to produce a finished garnet and by-products of ilmenite, zircon concentrate and Pyroxene. In addition, this plant was the first wet process recycling plant which was a significant change to the quality of garnet recovered from used garnet feed.

2018

GMA purchases Coos Bay, Oregon, USA property to build a West Coast processing plant focusing on the all important Californian markets.

.jpg?width=270&height=230&name=Rectangle%20707%20(10).jpg)

2020

.jpg?width=270&height=230&name=Rectangle%20707%20(10).jpg)

GMA was challenged in 2020 by the global business impacts of the COVID-19 pandemic.

GMA takes a sustainable approach to mining operations with a 2.5 MW wind farm and 1.1MW solar farm coming online in Port Gregory, West Australian operations. 70% of mine’s annual energy consumption will come from renewable energy sources.

.jpg?width=270&height=230&name=Rectangle%20708%20(1).jpg)

2021

.jpg?width=270&height=230&name=Rectangle%20708%20(1).jpg)

GMA’s Reserve Dry Processing plant located in New Orleans, Louisiana, USA sustained extensive damage from Hurricane Ida. This impacted GMA’s garnet supply to the Gulf region.

.jpg?width=270&height=230&name=Rectangle%20707%20(11).jpg)

2022

.jpg?width=270&height=230&name=Rectangle%20707%20(11).jpg)

GMA renews MRC (ASX:MRC) garnet offtake agreement and invests in $10 million loan funding to MRC for transitioning to higher value finished products.

.jpg?width=270&height=230&name=Rectangle%20708%20(2).jpg)

2023

.jpg?width=270&height=230&name=Rectangle%20708%20(2).jpg)

GMA announces major partner, Barton International, for garnet distribution and dual branding in selected markets within the United States.

Operations commence at a processing plant in Houston, Texas, USA, focusing on Gulf region markets and increasing reliability of garnet supply into the region.

GMA receives its first bulk shipment in 25 years into its newly redeveloped Coos Bay deep water port facility, offering improved supply and logistical benefits to the west coast of the United States of America.

Plans are finalized for the third-generation Wet Concentration Plant at the Port Gregory Mine site to process ore from this deposit for next 20-25 years.

Today

GMA Garnet™ is now a trademarked product, recognized globally as the standard in quality and excellence.

GMA products are sold in over 100 countries worldwide, and operations have expanded into 15 processing plants across the Middle East, Australia, America, and Europe. Over 500 employees are dedicated to maximizing our customers’ performance and building a sustainable future for all.

GMA ToughBlast™

GMA ToughBlast™ GMA PremiumBlast™

GMA PremiumBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ClassicCut™ 60

GMA ClassicCut™ 60 GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile