-1.png?width=2000&height=1125&name=Image%20Slider%20%20(1)-1.png)

.png?width=2000&height=1125&name=Image%20Slider%20%20(2).png)

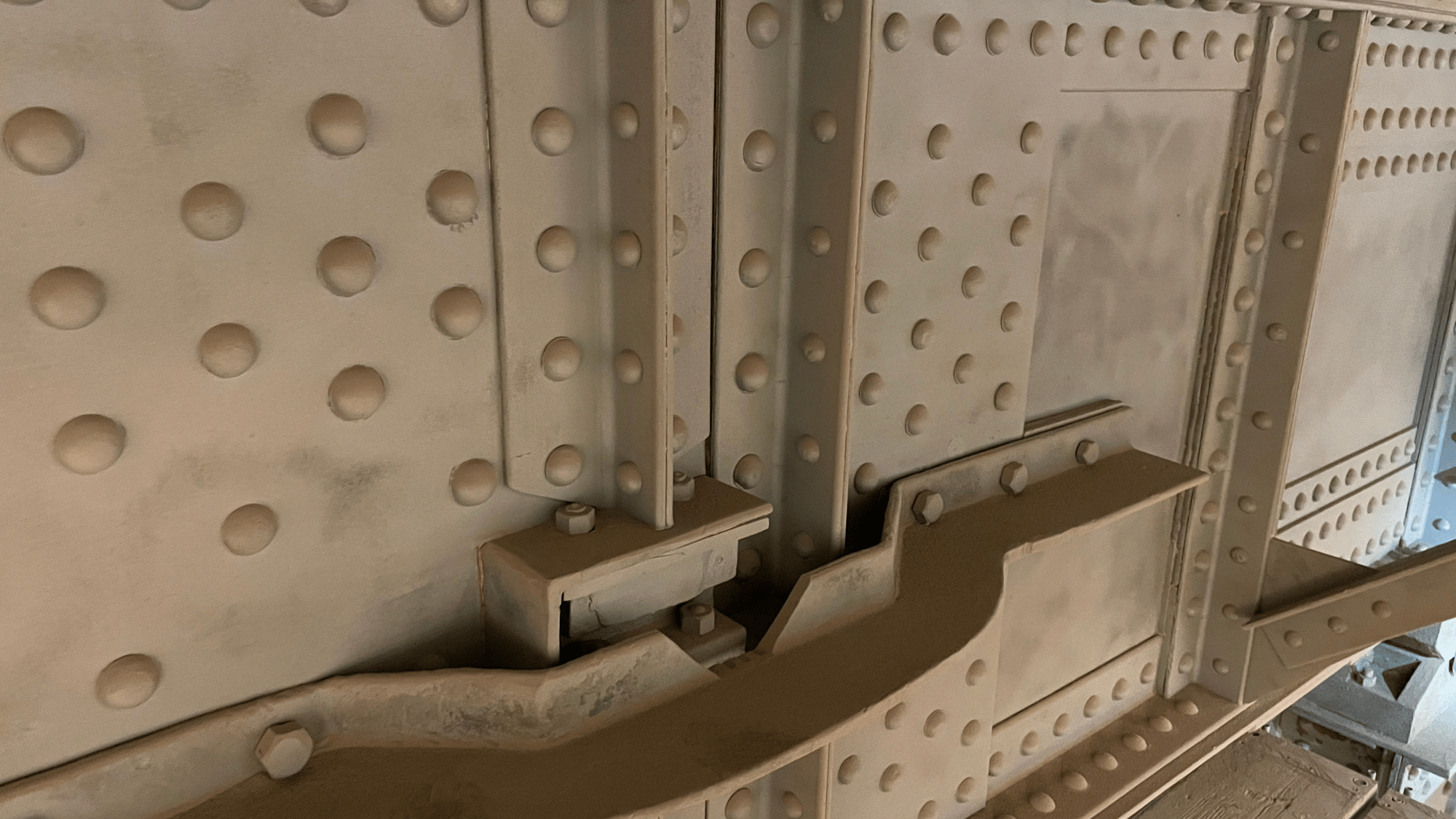

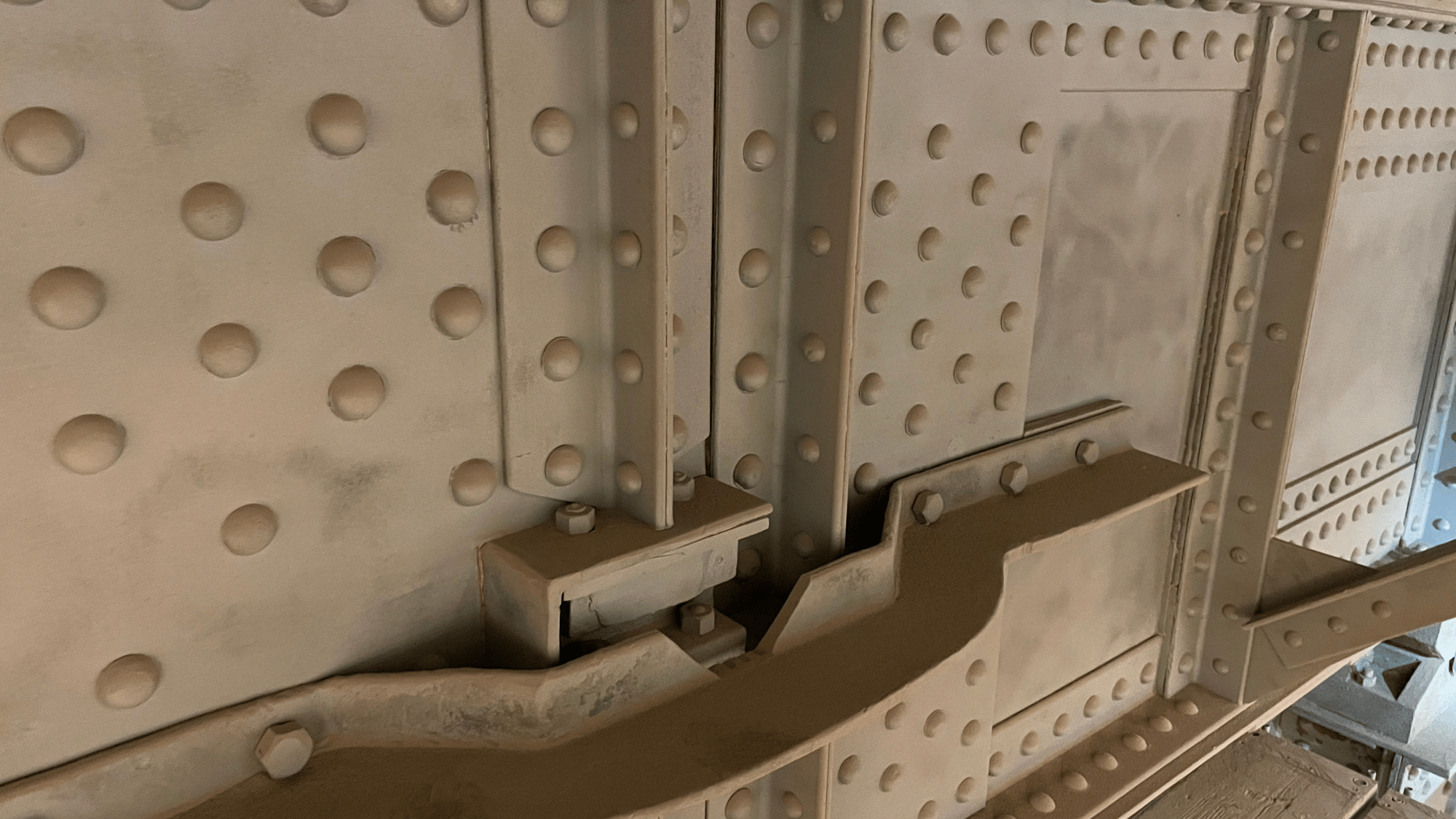

Structural refurbishment and surface preparation works.

Berlin, Germany

Refurbishment of the Berlin Postal Station

Comparing GMA PremiumBlast™ against slag abrasives.

Built in 1907, the postal station in Berlin, Germany was once an important logistics hub for managing mail and parcels. Over 100 years later, this fine industrial architecture is being refurbished and modernized while retaining its history and charm. One of the structural refurbishment works was sandblasting 4000 m² of complicated steel construction, including the original rivets. In addition, the old coating on these structures was up to 800 µm thick. The cleaned surface was then treated with a fire-protection coating.

Blasting and Painting specialist – CDP has been using synthetic slag abrasives for their major surface preparation works, and this was the first time GMA PremiumBlast™ Garnet was exclusively used for a project of this scale. Initially, Mr Udo Pohl, owner of CDP, was skeptical of garnet abrasives outperforming slag. After reviewing the performance data, he is convinced.

The blasting work which commenced in October 2022, was completed within 30 days. The four blasters allocated for the job completed the work two weeks ahead of schedule. Previously with slag abrasives, the blaster was required to stop every 40 minutes to refill the blast pot. After switching to GMA PremiumBlast™ the refill was down to every 90 to 120 minutes.

Savings

Using GMA PremiumBlastTM

CDP recorded a rate of 19.5 kg/m² of GMA Garnet™ used compared to 50 to 70 kg/m2 of conventional slags. The smaller quantity of garnet abrasives used—78 tonnes compared to at least 250 tonnes of slag—was also quicker to clean up and more cost-effective to dispose of.

In addition, numerous tests have recorded consumption rates lower than 12 kg/m² on less angled surfaces. According to Mr. Pohl, the blasted surface had the required surface profile with high surface cleanliness, which was almost perfect, even around the rivets.

-1.png?width=2000&height=1125&name=Image%20Slider%20%20(1)-1.png)

.png?width=2000&height=1125&name=Image%20Slider%20%20(2).png)

“From my professional point of view, the switch from slag abrasives to GMA PremiumBlast™ was the right decision for us, and our customers. The initial price per tonne may be higher, but the advantages on top of the economic benefits justify the initial investment. I would like to thank the GMA team for the good cooperation and the great job done.”

Mr. Udo Pohl

Owner of CDP

Subscribe to our e-newsletter for the latest news and events at GMA.