You’re currently viewing the Americas website.

You’re currently viewing the Americas website.

Would you like to switch countries or language?Blast Abrasives

Topics

Waterjet Cutting

Topics

Resources

Categories

Types

Categories

Topics

Waterjet Cutting Tech Tips English Global

The Future of Waterjet Cutting: Precision, Progress, and Possibility

As manufacturing technologies evolve, so do expectations around precision, material integrity, and environmental responsibility. For decades, waterjet cutting has proven its value across industries that demand accuracy without compromise. Now, as new technologies emerge, waterjet systems are positioned to play an even greater role in shaping the next generation of advanced manufacturing.

Cold Cutting in a High-Tech World

The manufacturing sector continues to invest in automation, digital monitoring, and sustainable operations. Amid these changes, cold-cutting processes like waterjet remain uniquely relevant. Unlike thermal cutting methods, waterjet eliminates heat-affected zones (HAZs), oxide inclusions, and material distortion — outcomes that are increasingly unacceptable in industries such as aerospace, defense, food processing, and medical manufacturing.

Future waterjet systems are expected to integrate more closely with smart factory frameworks, offering real-time monitoring of pressure, abrasive flow, and cut quality. These enhancements will not only improve efficiency but also enable tighter quality control and reduced material waste.

Hybrid Systems and Material Versatility

Innovation is already leading to the development of hybrid cutting systems that combine the precision of lasers with the flexibility of waterjets. Early research into waterjet-guided laser technology demonstrates the potential for such systems to handle an even broader range of materials and thicknesses — offering clean, heat-free cutting guided by the stability of a fine water stream.

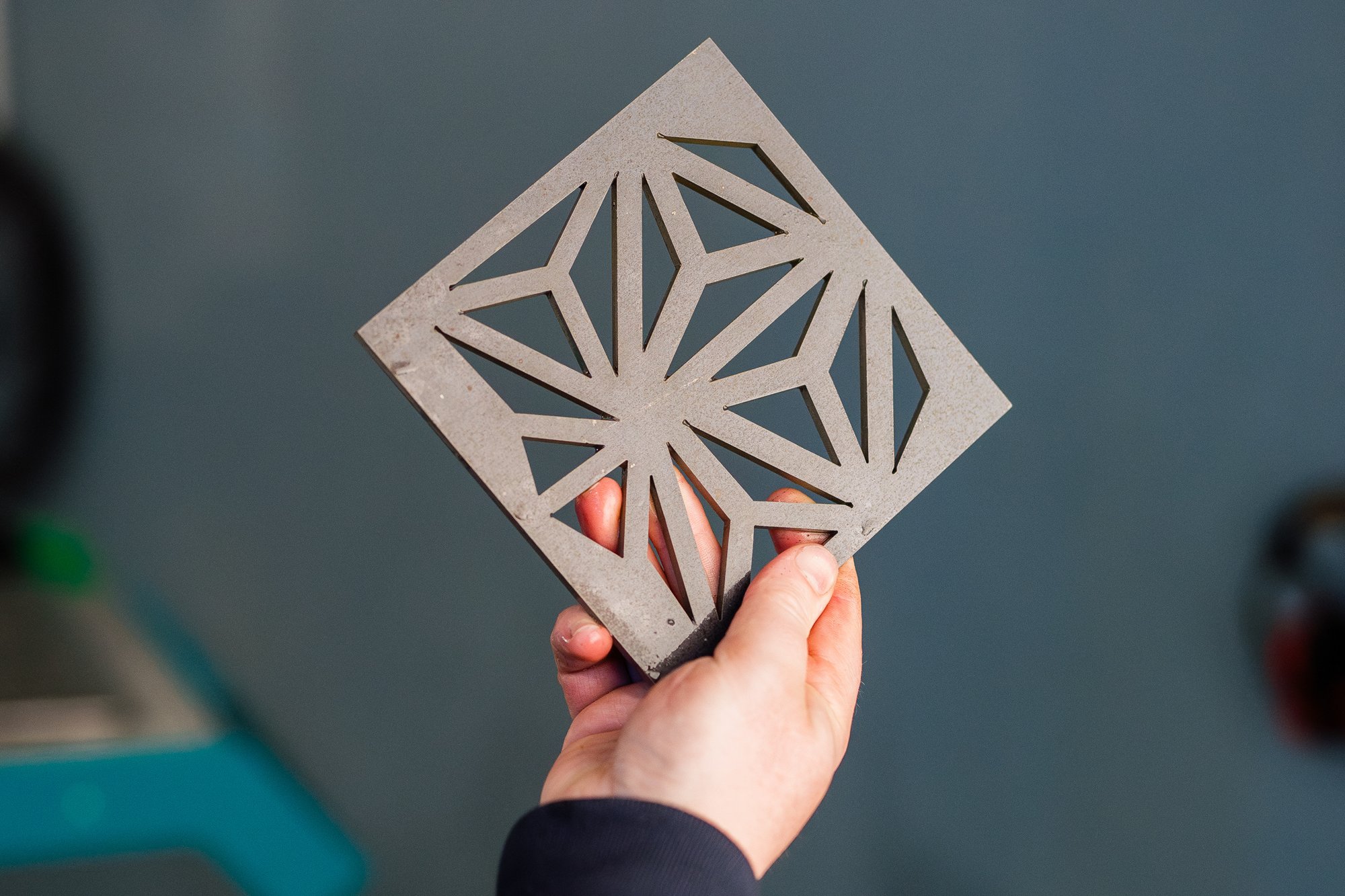

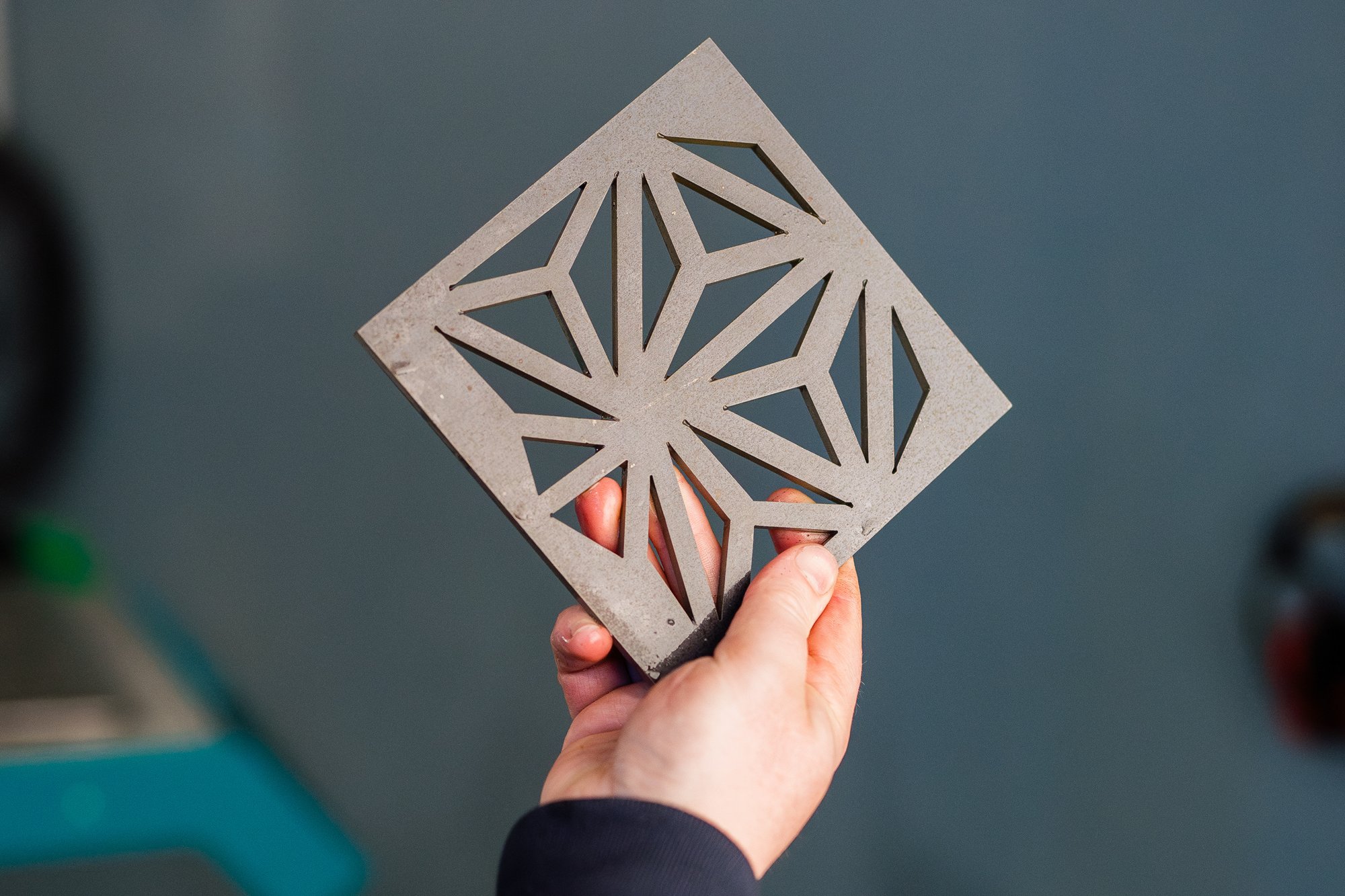

At the same time, waterjet/saw combination systems are becoming increasingly common in industries such as stone, ceramics, and composites. These integrated machines combine the speed of a saw blade for straight cuts with the precision of a waterjet for intricate shapes, patterns, and fragile materials. By automatically applying the most efficient method for each cut, hybrid systems deliver greater versatility, faster throughput, and reduced material waste — all within a single machine.

Advantages of Waterjet/Saw Combination Systems:

- Enhanced Versatility: Combines the speed of a saw for straight cuts with the precision of a waterjet for complex designs and delicate materials.

- Improved Productivity: Streamlines operations by eliminating the need to transfer materials between machines, significantly reducing downtime.

- Greater Precision and Faster Cutting: Provides optimal results for marble, granite, and advanced ceramics, achieving both speed and fine detail.

- Reduced Labor Costs: Automation and integration minimize manual handling and operator involvement, improving overall efficiency.

Sustainability and Resource Efficiency

As global industries push toward cleaner production, waterjet technology aligns naturally with this shift.

Waterjet cutting uses only water and garnet abrasive, producing no toxic fumes or airborne pollutants. In addition, initiatives such as GMA’s Garnet Return Program are helping manufacturers reduce waste and close the loop by recycling spent abrasive for reuse — supporting both environmental goals and operational efficiency.

Emerging energy-efficient technologies are also influencing equipment design. More efficient high-pressure pumps, improved nozzle systems, and automated abrasive control are helping reduce water and power consumption without compromising cut quality.

The Role of Research and Development

Ongoing research and development remain central to advancing waterjet technology. Collaboration between manufacturers, equipment developers, and abrasive suppliers continues to drive improvements in accuracy, automation, and sustainability.

Artificial intelligence and data analytics are likely to play a growing role in optimizing cut parameters — learning from each operation to enhance consistency, reduce material waste, and extend component life.

At GMA, we continue to explore how advancements in garnet processing, recycling, and engineered garnet products can further improve the performance and sustainability of waterjet systems worldwide.

Looking Ahead

The evolution of cutting technology will continue to be defined by precision, efficiency, and environmental performance.

While new approaches will emerge, the fundamental advantages of cold cutting — no heat, no hazards, no compromise — remain increasingly relevant to the needs of modern manufacturing.

To learn more about how waterjet technology compares with laser systems and where each fits into the future of industrial cutting, download GMA’s e-book.

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

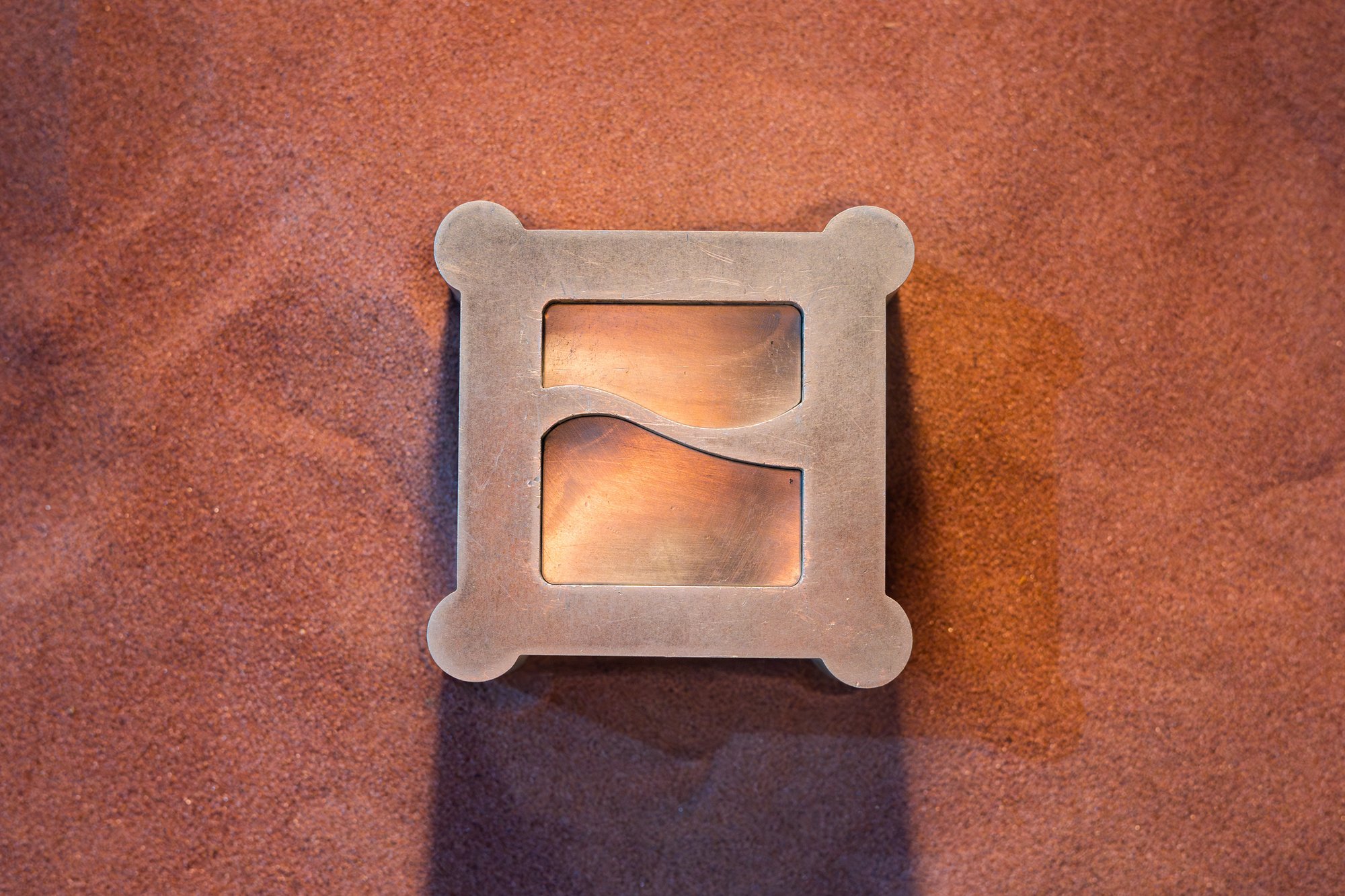

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile