Oil & gas blast abrasives

GMA works with major oil & gas asset owners globally to meet the highest standards in surface preparation, ensuring minimal downtime, coating longevity, and asset protection.

Get a cleaner surface fast, with minimized OSH risks

Choose a safer alternative for asset protection with our high-performing range of garnet abrasives for upstream, midstream, and downstream sectors.

High productivity

Achieve your specified surface profile faster than alternate abrasives.

Low consumption

Complete the job with far less abrasive, reducing costs in abrasive purchase, transport, and disposal.

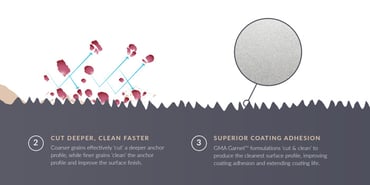

High peak density

Generate higher peak density over alternate abrasives for unmatched coating adhesion and integrity.

Low embedment

60% of the average slag-blasted surface is embedded with residual abrasive. Garnet results in minimal embedment.

Low dust

GMA Garnet™ offers the closest thing to dustless blasting, drastically improving operator visibility and reducing site contamination.

Low safety risk

Garnet is an inert mineral with little to no heavy metals creating worker risks or environmental hazards.

A week's work in one day with GMA Newsteel™

When project timelines tightened, a leading industrial coatings contractor unlocked 71% more productivity than waste slag — at 15% less cost.

Onshore and offshore refineries

Offshore surface preparation presents a number of challenges: harsh environments, remote locations, worker health & safety risks, and environmental contamination risks, to name a few.

That’s why GMA works with asset owners to ensure our blasting abrasives deliver:

- The required surface profile with high peak density for strong coating adhesion

- Exceptional surface cleanliness and minimal embedment for optimal substrate integrity and minimized risk of blistering, corrosion, and coating failure

- High cleaning efficiency to significantly reduce down time

- Low abrasive consumption to minimize material transport and storage.

Tanks, terminals, and pipelines

GMA Garnet™ is a staple in fabrication and maintenance work due to its high blasting rate and low dust emissions.

- Performance: Cut and clean coatings faster, and get a consistent surface while using less abrasive media.

- Low dust: Reduce health & safety risks, and significantly increase operator visibility inside tanks and confined spaces.

- Maintenance: Our unique engineered blends are ideal for cleaning heavily pitted steel tank floors and linings.

- Fabrication: GMA NewSteel™ is the fastest abrasive on the market for hard mill scale removal.

.jpg?width=500&height=580&name=mask%20(1).jpg)

Safely create clean, consistent surfaces

Find out how GMA can produce the range of surface profiles that your protective coatings require — safely, efficiently, and without disrupting your facility.

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile