You’re currently viewing the Americas website.

You’re currently viewing the Americas website.

Would you like to switch countries or language?Blast Abrasives

Topics

Waterjet Cutting

Topics

Resources

Categories

Types

Categories

Topics

Waterjet Cutting Tech Tips English Global

Selecting the right cutting technology for your project

There are various industrial cutting technologies available in the market such as waterjet cutting, laser, plasma and Electrical Discharge Machining (EDM).

Selecting the right cutting technology for your project may depend on a number of variables such as the type and thickness of the material, the level of precision and quality of the cut.

Let’s explore these options including the capabilities and advantages of each technology.

Abrasive Waterjet Cutting

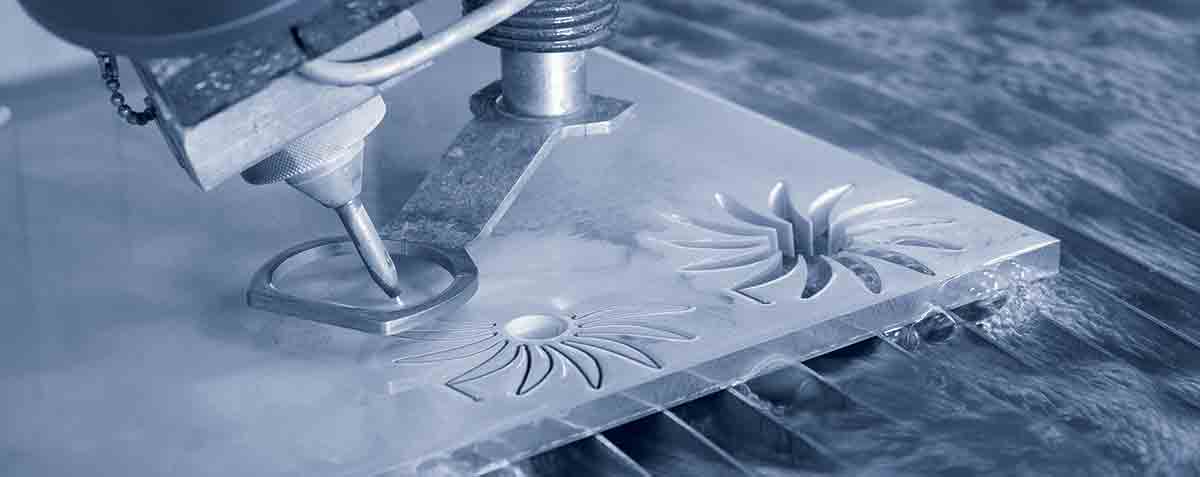

Waterjet cutting is a cold cutting process which uses a combination of garnet abrasives and high-pressure stream of water to cut almost any material such as steel, titanium, stone, wood and glass. The pressure applied during the cutting process can range from 60,000 to 90,000 psi.

Plasma Cutting

Plasma cutting is a thermal process where electrically heated ionised gas – plasma is forced through a small nozzle orifice in the torch; it generates an electric arc cuts through the material by melting it at high temperature of up to 22,000° C (40,000° F).

Laser Cutting

Laser cutting is also a thermal process where a focussed beam is directed at the material. The material either melts, burns, vaporises or gets blown away by a jet of gas.

Electrical Discharge Machining (EDM)

Also known as spark machining, EDM is a production process which directs high-frequency spark discharges from a graphite or soft metal tool at the material to cut/remove electrically conductive materials such as hardened steel or carbide.

The capabilities and advantages of each cutting technology:

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile