You’re currently viewing the Americas website.

You’re currently viewing the Americas website.

Would you like to switch countries or language?Blast Abrasives

Topics

Waterjet Cutting

Topics

Resources

Categories

Types

Categories

Topics

Abrasive Blasting Tech Tips English Global

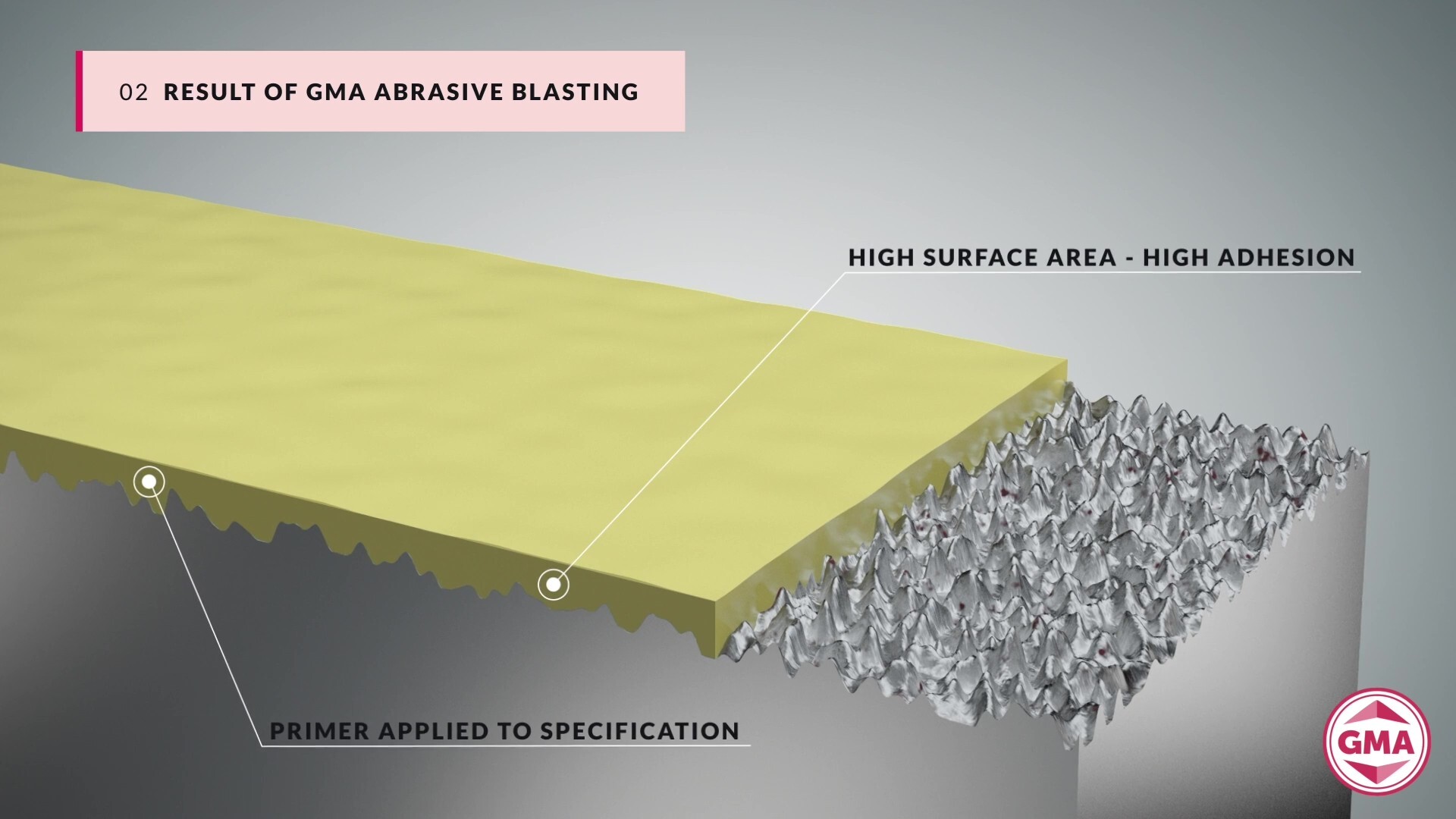

High Peak Density for Enhanced Coating Adhesion

The Importance of Peak Density in Coating Applications

The effectiveness of a coating system depends on the profile of the prepared surface. Peak density—the number of peaks per unit area—is a key factor that determines the adhesion strength of a coating. Higher peak density provides greater surface area for coatings to bond, improving adhesion and reducing the likelihood of coating failure.

Slag Abrasives: Challenges with Inconsistent Profiles

Blasting with slag abrasives often results in low peak density due to their irregular particle shapes and inconsistent performance. This creates several challenges:

- Inconsistent Surface Profile: Variability in profile leads to uneven coating thickness.

- Thicker Primer Coats: More material is required to cover the surface, increasing costs and labor.

- Risk of Delamination: Thick primer layers are prone to delamination, particularly in harsh environments.

GMA Garnet™: Delivering High Peak Density

GMA Garnet™ abrasives provide a consistent surface profile with high peak density, offering significant benefits:

- Uniform Adhesion: Consistent profiles allow primers to be applied within specified thickness ranges.

- Optimized Coating Performance: Higher peak density improves bonding strength, reducing the risk of coating delamination.

- Efficient Material Use: With a smoother, more uniform surface, less coating material is required, saving costs and reducing waste.

Topics

Abrasive Blasting

Tech Tips

English

Global

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile