You’re currently viewing the Americas website.

You’re currently viewing the Americas website.

Would you like to switch countries or language?Blast Abrasives

Topics

Waterjet Cutting

Topics

Resources

Categories

Types

Categories

Topics

Waterjet Cutting Tech Tips English Global

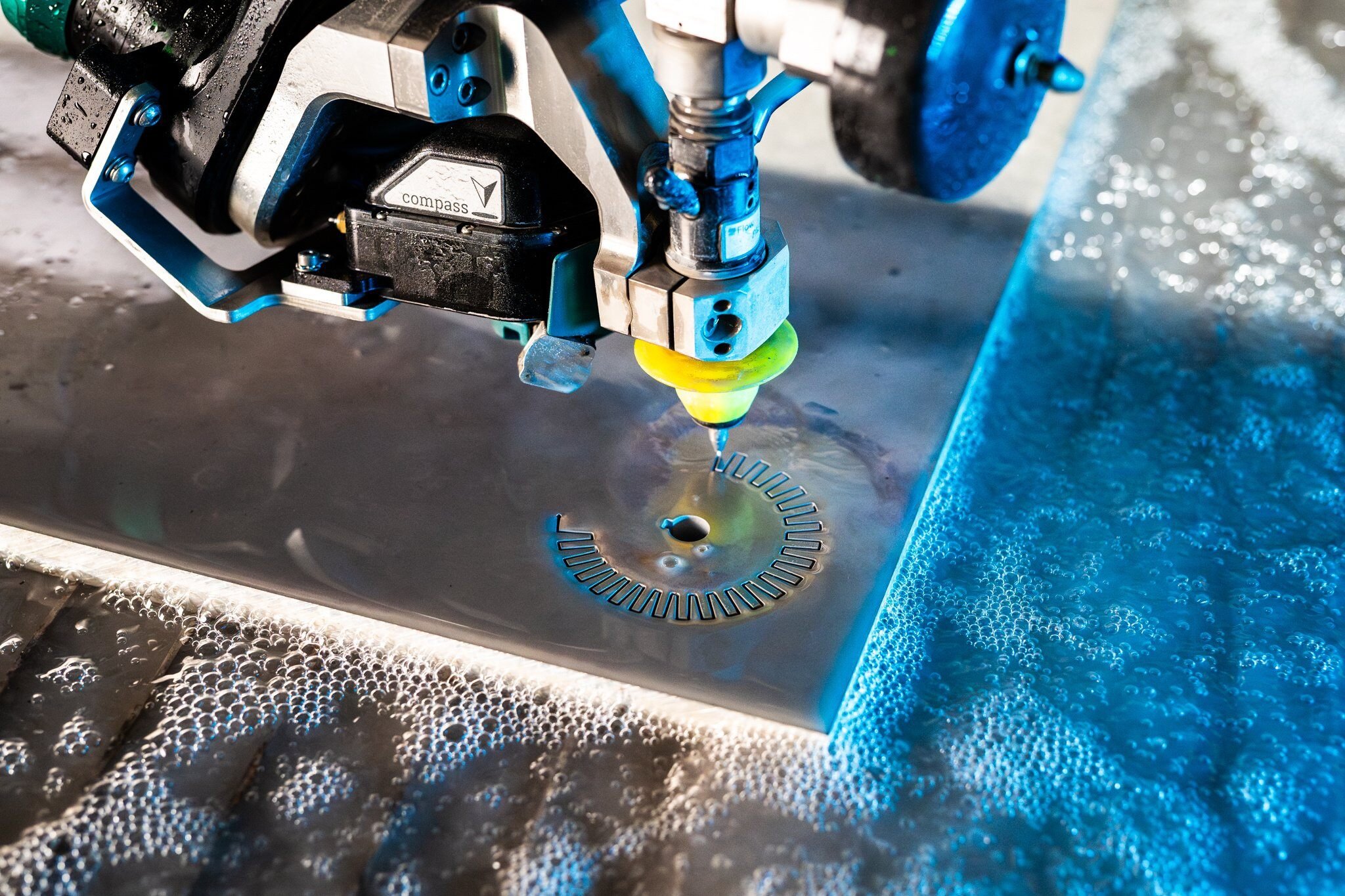

Enhancing Edge Quality in Waterjet Cutting: Mastering Precision

In abrasive waterjet cutting, one of the key goals is to achieve an edge quality that not only meets aesthetic standards but also ensures the cut part's functionality and precision. Edge quality, which involves the smoothness and shape of the cut edge, plays a crucial role in the overall outcome of a project.

The industry uses a scale ranging from Quality 1 (Q1) to Quality 5 (Q5) to classify edge quality, with Q5 denoting the highest level of precision and smoothness.

Understanding the Significance of Edge Quality

The quality of an edge is instrumental in determining how well parts fit together in assembly, whether additional processing is required, and the final functionality of the component. High-quality edges (Q4-Q5) are particularly important in sectors that demand high precision, such as aerospace, automotive, and medical devices, where the slightest discrepancy can make a significant difference.

Nevertheless, aiming for the highest edge quality has its compromises, mainly in terms of speed. There's an inverse relationship between cutting speed and edge quality; aiming for the utmost precision (Q5) significantly reduces cutting speed. This reduction could extend the completion time of a project by two to threefold, especially when comparing Q5 to lower qualities like Q3.

Navigating the Cost-Time-Quality Triangle

In abrasive waterjet cutting, time translates directly into cost. Longer cutting times increase expenses, not only through the direct cost of operating the machinery but also due to delays in production and delivery. Therefore, choosing the right edge quality involves weighing the desire for a perfect finish against the need for efficient production schedules.

Maximizing Edge Quality with GMA ClassicCut™ Garnet Abrasives

To strike a balance between quality and efficiency, GMA presents ClassicCut™ 80 and ClassicCut™ 120 garnet abrasives. These abrasives are chosen for their hardness, density, toughness, high purity, and ideal particle size distribution, enabling them to provide an excellent cut while maximizing cutting speeds.

The Role of Nozzles and Orifices

Alongside selecting the right abrasive, the choice of nozzles and orifices is critical for superior edge quality. Nozzles such as ROCTEC APX and ROCTEC 500 are recommended for precision cutting across various sectors, including aviation, aerospace, automotive, defense, and the arts. These nozzles support long, continuous cuts and help maintain tight tolerances over time, reducing waste from early nozzle wear.

Choosing the correct orifice material also impacts edge quality significantly. Diamond or tetraCore orifices are preferred over ruby or sapphire because they produce a more cohesive water stream, which enhances cutting speed, precision, and, ultimately, edge quality.

Selecting the optimal edge quality for your project requires a deep understanding of the compromises between cutting speed, cost, and the desired finish. By selecting the right combination of abrasive, nozzle, and orifice, you can achieve the best possible results for your project without sacrificing efficiency. Our technical teams are ready to provide personalized advice to help you attain the highest edge quality at the fastest cutting speeds.

Click HERE to discover the full potential of abrasive waterjet cutting and how to take your projects from basic cuts to meticulously precise finishes.

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile