You’re currently viewing the Americas website.

You’re currently viewing the Americas website.

Would you like to switch countries or language?Blast Abrasives

Topics

Waterjet Cutting

Topics

Resources

Categories

Types

Categories

Topics

Abrasive Blasting Tech Tips English Global

Engineered Blends: GMA Garnet’s Optimal Balance of Cutting and Cleaning

Balancing Cutting Power and Cleaning Efficiency

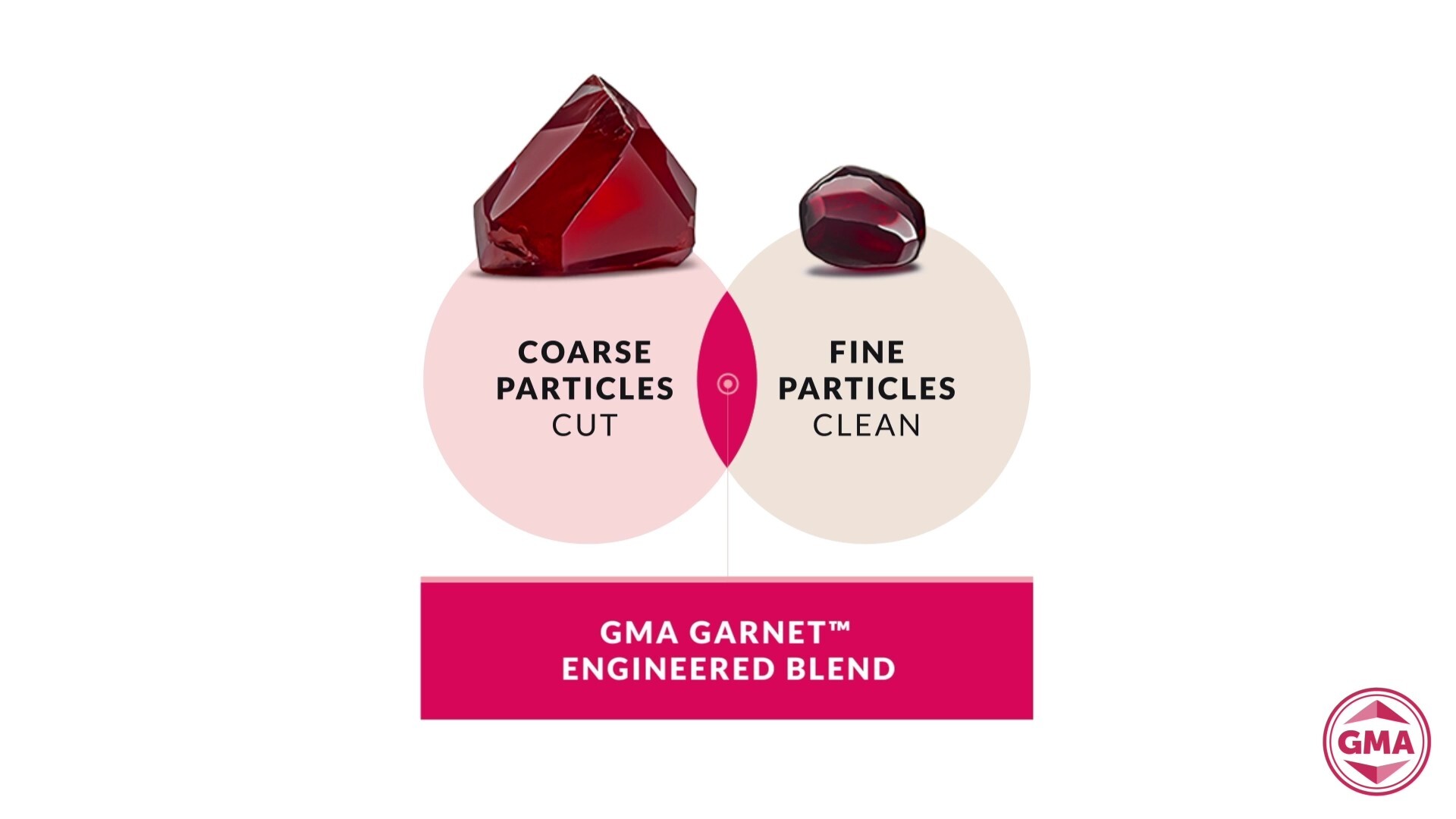

Effective abrasive blasting requires a balance of cutting power to remove tough coatings and cleaning ability to prepare the surface for coating. Abrasives that are too aggressive can damage the substrate, while those that lack cutting power may not remove contaminants effectively. Engineered blends, like those developed by GMA Garnet™, are designed to achieve this balance.

How Engineered Blends Work

- Coarse Particles for Cutting: Larger, angular particles effectively cut through heavy rust, thick coatings, and tough contaminants.

- Fine Particles for Cleaning: Smaller particles clean the surface, ensuring it is free of debris and ready for coating.

GMA Garnet™ Engineered Blend: Key Advantages

GMA Garnet™ engineered blends combine coarse and fine particles to deliver superior performance:

- Minimal Embedment: Reduces contamination of the substrate.

- Consistent Surface Profile: Ensures uniformity, crucial for coating adhesion.

- High Peak Density: Provides a surface with maximum adhesion potential.

- Cleaner Surface: Removes all debris, leaving the substrate coating-ready.

Topics

Abrasive Blasting

Tech Tips

English

Global

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile