-1.png?width=769&height=720&name=Tables%20For%20Case%20Studies%20%20(1)-1.png)

You’re currently viewing the Americas website.

You’re currently viewing the Americas website.

Would you like to switch countries or language?Blast Abrasives

Topics

Waterjet Cutting

Topics

Resources

Categories

Types

Categories

Topics

Abrasive Blasting Case Studies English GAC Americas APAC Europe Middle East%20-%20banner%20.jpg)

Comprehensive Risk Assessment of Abrasive Products

Test Details

Location

GMA’s La Porte, Texas, USA

Period

April & November 2019

Products Tested

Indoor ‘Worst Case’ Scenario: 21 abrasive product. Outdoor ‘Field Representative’ Scenario: 9 abrasive products

Sampling Locations

60-minute tests. Indoor: Personal, 12.5 ft, and 20 ft. Outdoor: 20 ft downwind

Exposure Limits Tested

Arsenic, Barium, Beryllium, Cadmium, Chromium, Lead, Manganese, Nickel, Silica (Crystalline), Respirable Dust

Blast abrasives contain highly hazardous materials, requiring rigorous industrial hygiene exposure assessments.

A detailed risk analysis was conducted at GMA’s La Porte, Texas facility by HSE Solutions, Inc. The study evaluated 21 abrasive products indoors and 9 outdoors over two periods in 2019, with the objective to rank these products based on their respirable bulk limits and assess their potentially hazardous nature.

Methodology

The assessment involved collecting air samples from various locations, including personal samples and downwind sampling points, both indoors and outdoors. The samples were tested for the presence of 18 heavy metals, including Beryllium, Arsenic, Cadmium, and Silica (Crystalline). The analytical methodologies employed were NIOSH 7300M, 7303M, 0600, and OSHA 142 V4.

The primary goal was to determine if the abrasives contained enough hazardous material to warrant industrial hygiene exposure assessments during blasting operations.

Dust: The Top Problem of Abrasive Blasting

-1.png?width=769&height=720&name=Tables%20For%20Case%20Studies%20%20(1)-1.png)

Bulk Sample Analysis and Risk Assessment

The risk assessment of abrasive products involved a thorough analysis of bulk samples against their Occupational Exposure Limits (OEL) and corresponding air sample results. This analysis aimed to determine the potential health risks posed by different abrasive products when used in industrial applications, particularly during blasting operations.

Bulk Sample Analysis

The bulk samples were collected from each abrasive product and analyzed for their content of 18 heavy metals, including Arsenic, Beryllium, Cadmium, Chromium, Lead, Manganese, Nickel, and Silica (Crystalline). These metals are known to pose significant health risks if inhaled or exposed to workers over extended periods. The analysis focused on comparing the concentration of these metals in the bulk samples with their respective OELs, a standard set by regulatory bodies to protect workers from harmful exposure.

Risk Levels Definition

The risk levels for each abrasive product were determined based on the Bulk/OEL ratio, which compares the concentration of a hazardous material in the bulk sample to its Occupational Exposure Limit. This ratio provides insight into whether the amount of hazardous material present in the product could potentially exceed safety thresholds during use.

- Greater Risk: A Bulk/OEL ratio of 2000 or higher indicates a "Greater Risk”: the hazardous material concentration is significantly high and could exceed OSHA's Permissible Exposure Limit (PEL) over an 8-hour average. Products with this ratio pose a substantial health risk and require stringent safety measures during use.

- Heightened Risk: A Bulk/OEL ratio between 65 and 1999 was classified as a "Heightened Risk." Although the concentration of hazardous materials in these products did not exceed the OSHA PEL when averaged over an 8-hour TWA, they still pose a moderate health risk. These products require careful monitoring and appropriate protective measures to ensure worker safety.

Crystalline Silica Risk

Crystalline Silica, a known carcinogen, was detected in several samples. If the concentration of Crystalline Silica exceeded the OSHA PEL when averaged over an 8-hour TWA, it was assigned a higher risk value. This increased risk highlights the need for additional precautions when handling or using abrasive products containing Crystalline Silica.

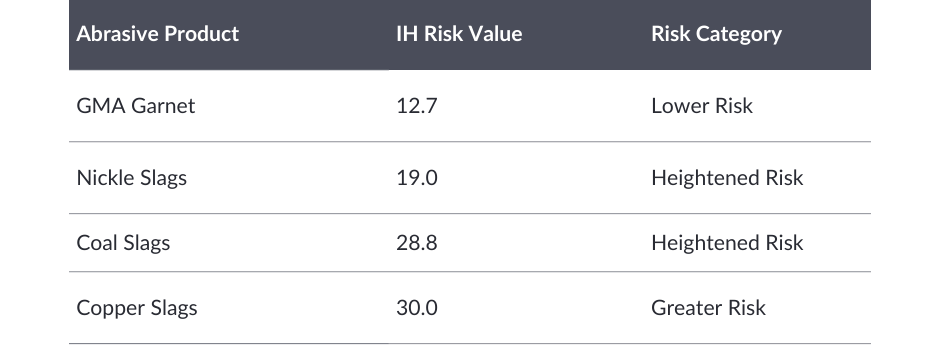

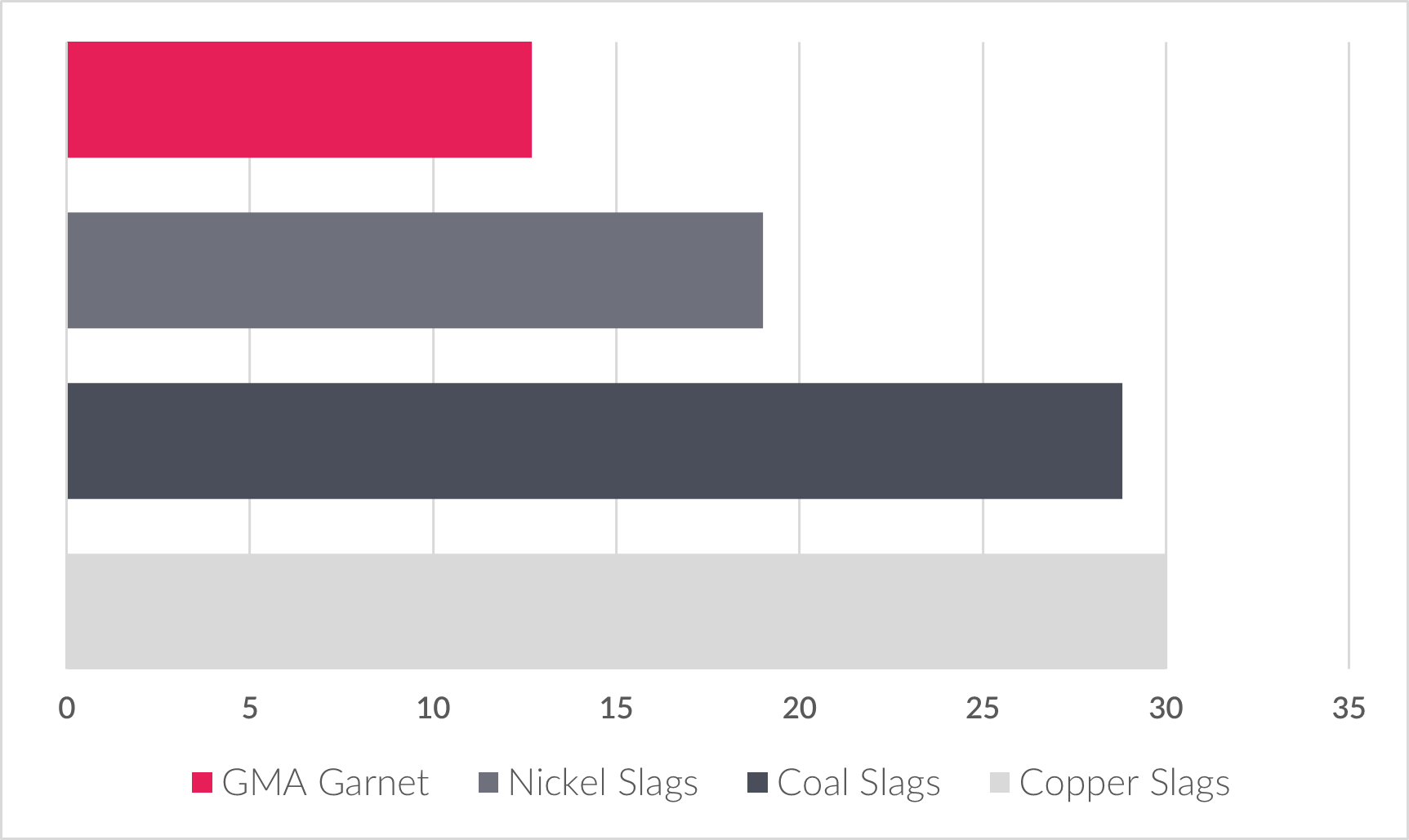

Product Health Risk Analysis Results

The final step in the assessment involved assigning risk values to each abrasive product based on the Bulk/OEL ratio and the presence of Crystalline Silica. The results indicated significant variations in risk levels among different abrasive products, with some posing much higher health risks than others.

GMA Garnet™: With an IH Risk Value of 12.7, GMA Garnet™ was identified as a lower-risk product. It falls well below the threshold for both Greater and Heightened Risk categories, making it a safer choice for abrasive blasting operations.

Nickel, Coal, and Copper Slags: These products were found to have higher IH Risk Values, indicating a greater potential for hazardous exposure. Copper Slags with a risk value of 30.0, fall into the Greater Risk category, warranting significant concern and the need for enhanced protective measures.

GMA Garnet™: With an IH Risk Value of 12.7, GMA Garnet™ was identified as a lower-risk product. It falls well below the threshold for both Greater and Heightened Risk categories, making it a safer choice for abrasive blasting operations.

Nickel, Coal, and Copper Slags: These products were found to have higher IH Risk Values, indicating a greater potential for hazardous exposure. Copper Slags with a risk value of 30.0, fall into the Greater Risk category, warranting significant concern and the need for enhanced protective measures.

Figure 1: Industrial Hygiene Risk Values for Various Abrasive Products

Source: Industrial Hygiene Abrasive Products Assessment Report – 2019/2020, Houston Texas, HSE Solutions, Inc.

Discussion

- Surprising Results: Despite low amounts of heavy metals in many slag abrasives, high respirable results suggest that highly friable abrasives (such as slags) release more hazardous chemicals and heavy metals into the air.

- OSHA Regulations: Even with stringent OSHA regulations and low threshold limits, heavy concentrations of hazardous materials can still be released.

- SDS Limitations: Safety Data Sheets (SDS) provide limited information about hazardous materials like heavy metals.

- PPE Limitations: While PPE protects blasters, other personnel on the blast site might still be exposed to high levels of hazardous materials.

Environmental Risk Considerations

The environmental risk is correlated with the concentration of heavy metals in the product. Higher concentrations of these metals increase the probability of air concentrations exceeding the limit, thereby elevating the environmental risk.

Recommendations

- Pre-Purchase Analysis: Before purchasing or trialing abrasive products, request a bulk analysis assessment from the supplier or contractor.

- Qualitative Risk Assessment: Request a comprehensive qualitative risk assessment to ensure the safety of workers.

- Selection of Abrasives: Choose abrasives with lower IH Risk Values to minimize potential hazards.

In Summary

The risk assessment revealed that certain abrasives, particularly slag-based products, pose a higher health risk due to their ability to release hazardous materials during blasting. GMA Garnet™, with a lower IH Risk Value, presents a safer alternative for blasting operations. For safety-critical environments, it is essential to perform a detailed analysis and select abrasives that minimize the exposure to harmful substances, ensuring the safety of all personnel involved.

By understanding and mitigating these risks, engineers, corrosion specialists, specification specialists, industrial hygienists and HSE managers can make informed decisions to protect workers and comply with regulatory standards.

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile