ROCTEC™ Nozzles

The industry leading waterjet cutting nozzles. Minimize nozzle wear and maintain reliable precision performance and productivity.

Kennametal ROCTEC™ Nozzles

Unrivaled waterjet cutting performance

ROCTEC™ abrasive waterjet mixing tube nozzles are at the forefront of waterjet cutting technology, made with a proprietary process and advanced materials.

ROCTEC nozzles allow longer cutting periods while maintaining precision performance, perfectly complimenting GMA Garnet waterjet abrasives.

ROCTEC APX Nozzles

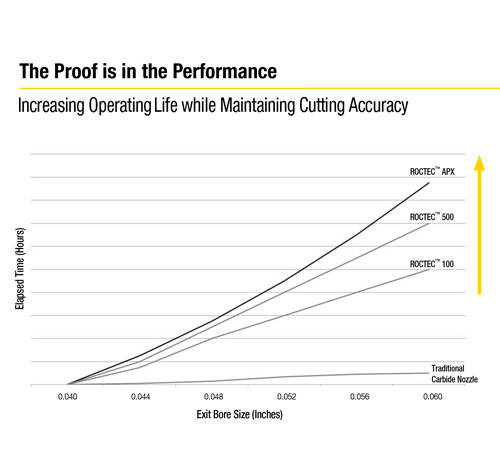

The new Kennametal APX ROCTEC® nozzles provide 20 percent greater nozzle life than the industry-leading ROCTEC® 500 waterjet series, significantly outperforming conventional tungsten carbide nozzles.

Excellent for precision cutting applications in aviation, aerospace, automotive, defense and medical industries where long, uninterrupted cuts or close tolerances have to be maintained for long periods to maintain parts integrity or minimise expensive scrap from premature nozzle failure.

Roctec 500 Nozzles

The trusted waterjet abrasive nozzle for consistent, accurate cutting. Made from composite carbide, a tungsten carbide-based material made by the Rapid Omindirectional Compaction (ROC) process, ROCTEC 500 nozzles resist high heat and are extremely durable.

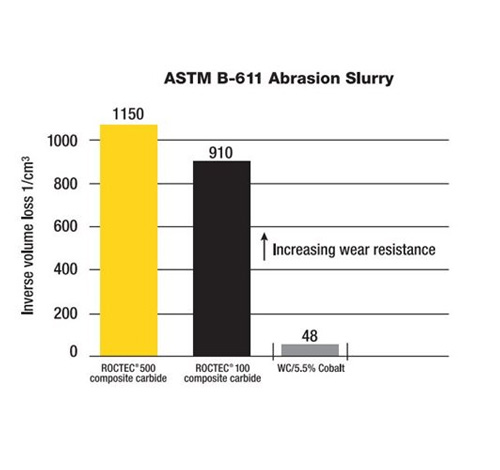

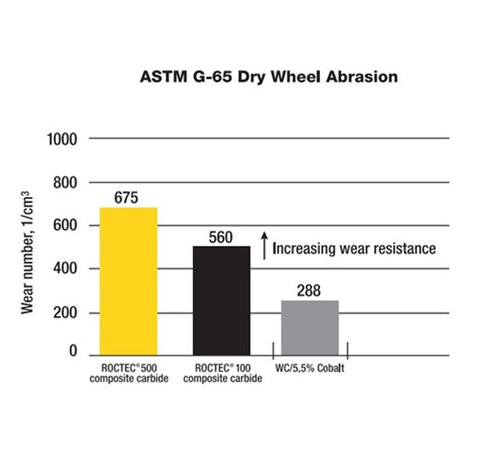

- Wear resistance: 24 times greater than conventional tungsten carbide/cobalt nozzles in ASTM B-611 Abrasion Slurry Test. 2.3 times greater than tungsten carbide/cobalt in ASTM G-65 Wheel Abrasion Test.

- Consistency: Superior bore growth improves cutting accuracy and tolerance levels.

- Superior performance: Faster cutting speed & greater dimensional accuracy against ROCTEC® 100 and tungsten carbide/cobalt nozzles.

- Operational efficiency: Less machine downtime and longer nozzle lifespan against ROCTEC® 100 and tungsten carbide/cobalt nozzles.

Roctec 100 Nozzles

Industry workhorse, fit-for-use performance. Kennametal ROCTEC® 100 nozzles are made from composite carbide, a tungsten carbide-based material made by the Rapid Omindirectional Compaction (ROC) process.

ROCTEC nozzles resist high heat and are extremely durable for waterjet cutting. Compared to Standard tungsten carbide nozzles, ROCTEC® 100 nozzles provides superior cutting performance and demonstrate wear resistance 2.5 times greater than tungsten carbide/cobalt nozzles. The ROCTEC® 100 composite carbide nozzles is the enabler for today's modern waterjet abrasive machinery.

Speak to an expert

GMA's waterjet industry experts can help you select the right garnet abrasive and wear resistant parts to optimise your waterjet cutting operations. Discover the full range of waterjet abrasive and connecting parts for your machines today.

GMA ToughBlast™

GMA ToughBlast™ GMA PremiumBlast™

GMA PremiumBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ClassicCut™ 50

GMA ClassicCut™ 50 GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile