Reduce dust levels by up to 80%

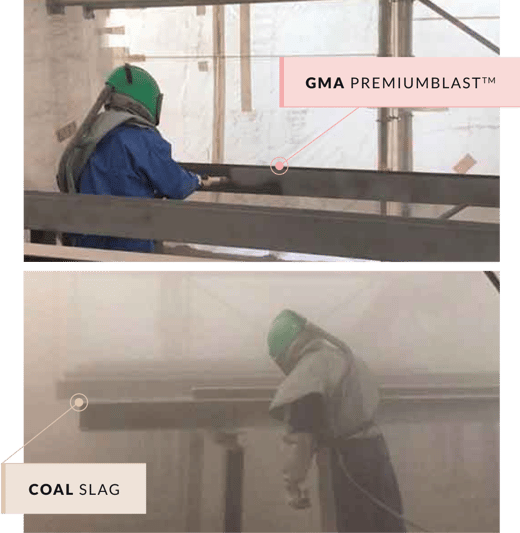

Abrasive blasting doesn’t have to be dusty business. GMA Garnet™ enables low dust blasting for unparalleled visibility, precision, and safety during blasting operations.

Don’t let dust slow down your project

Contractors and site managers dealing with slag abrasives understand the impact of dust. It reduces visibility, slows progress, and poses airborne hazards. Often, other trades are taken off the job to manage these issues during blasting. However, this disruption stems directly from using waste slag, not from the blasting process itself. GMA Garnet™ abrasives produce up to 80% less dust, helping maintain a safer and more efficient worksite.

Low dust abrasive enables day and night blasting

A shipyard in New York Harbor recently switched blasting abrasives to trial GMA ToughBlast™ and discovered efficiencies across the operation. Blast cleaning was typically conducted at night due to the high dust levels created by slag, limiting visibility and affecting nearby workers. The trial showed GMA Garnet’s lower dust emissions significantly improved visibility and safety on site while eliminating the scheduling constraints of dusty slags.

GMA Garnet™ is a low dust blasting media

Dust generated during abrasive blasting results from abrasive particles fracturing upon impact with the surface, as well as the removal of paint or surface contaminants. However, our garnet’s inherent hardness, toughness, density, and angularity offer a unique advantage.

GMA Garnet™ is a remarkably tough natural mineral, up to 500% tougher than waste slags. It is highly resistant to fracturing, compared to slag abrasives which turn to dust upon impact.

GMA Garnet™ optimizes blasting

Optimal results

GMA Garnet™ is an exceptionally tough and hard abrasive compared to slags and other alternatives, resisting breakdown on impact for a higher surface profile.

Minimal dust

GMA Garnet’s low friability creates minimal dust while blasting, allowing clearer operator visibility and avoiding site contamination.

Protects workers

Less dusty abrasives, like GMA Garnet™, minimize exposure to airborne dust and are safer for blasters, onsite workers, and surrounding communities.

Increases productivity

Using low dust GMA Garnet™ prevents avoidable stop-start blasting and site disruption to promote efficiency across the operation.

Lorem ipsum dolor sit

Recommended resources

Frequently asked questions

Choose the tougher, low-dust blasting media. To find out more about GMA Garnet™ and switching to garnet abrasives, visit the FAQs library.

Why is dust generation an important factor in abrasive blasting operations?

Dust generation significantly impacts the safety, visibility, and environmental conditions of the worksite. High levels of dust can disrupt other trades, contaminate the site, and pose severe health risks to workers. Dust can carry toxic particles such as arsenic, cadmium, and beryllium, which can cause lung damage and other serious health issues if inhaled.

Using an abrasive that produces less dust, like GMA Garnet™, can improve visibility, create a safer work environment, and reduce contamination risks.

How does GMA Garnet™ compare to slag abrasives in terms of dust production?

GMA Garnet™ produces up to 80% less dust compared to slag abrasives. Slag abrasives, being waste products of burning coal or producing metals, are highly friable and shatter into fine particles upon impact, creating large amounts of dust. This dust can reduce visibility, contaminate the site, and expose workers to harmful heavy metals.

In contrast, GMA Garnet is much tougher and more resistant to fracturing, resulting in significantly less dust production, making it a cleaner and safer option for abrasive blasting.

What are the benefits of using GMA Garnet™ in terms of dust control?

Using GMA Garnet for abrasive blasting offers several benefits related to dust control:

- Reduced Dust Production: GMA Garnet generates up to 80% less dust than slag abrasives, reducing contamination and health risks.

- Improved Visibility: Lower dust levels enhance operators’ visibility, allowing for more precise and efficient blasting.

- Safer Environment: Less dust means a safer environment for nearby workers, reducing their exposure to hazardous particles.

- Easier Containment: The dust produced by GMA Garnet is easier to contain and manage, minimizing the impact on other trades and surrounding areas.

Can GMA Garnet™ be used in enclosed or confined spaces?

Yes, GMA Garnet™ is ideal for use in enclosed or confined spaces due to its low dust generation. This improves visibility and air quality, making it safer for operators working in such conditions.

Speak to your local GMA Garnet™ expert

Lorem ipsum dolor sit

Donec consequat dolor vulputate enim rhoncus, non maximus ligula venenatis?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Nunc nec arcu eget lectus dapibus congue sed a lorem nec est scelerisque faucibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Arcu eget lectus dapibus congue?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Nunc nec arcu eget lectus dapibus congue sed a lorem nec est scelerisque faucibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.