Reducing costs goes beyond just price

Operational efficiency is about every facet of the project — mastering productivity, minimizing consumption, optimizing labor, and streamlining waste — to ensure jobs are completed on time and on budget.

What is your abrasive really costing you?

The true cost of your blasting abrasive is about more than consumption. Find out how much you can save on your next project with the GMA TruCost Calculator. It takes minutes to estimate the amount of GMA Garnet™ required for a project compared to other abrasives, and see itemized costs of material, labor, equipment, cleanup, and removal.

Try the GMA TruCost Calculator for an accurate abrasive consumption estimate and clearer project planning.

Cut Consumption, Boost Savings

How much abrasive do you really need to get the job done? With GMA Garnet™ blast abrasives, you can use up to 50% less to achieve the same results, leading to overall lower project costs. This reduction cuts costs not only for the abrasive itself but also for transport, disposal, labor, and equipment.

Tougher grains. Lower costs.

Minimized wastage

GMA Garnet™ delivers more value from less abrasive, reducing product wastage. There’s far less to clean up and less potential for waste disposal in landfill.

Efficient preparation

With its inherent toughness, hardness, angularity, and density, GMA Garnet™ requires fewer passes to prepare a surface compared to slag abrasives.

Unparalleled performance

GMA’s exclusive range of engineered blends cut and clean efficiently, dramatically lowering blast abrasive consumption.

Lower overall costs

Reduced abrasive consumption leads to lower operational and landfill costs, driving down overall cost per project.

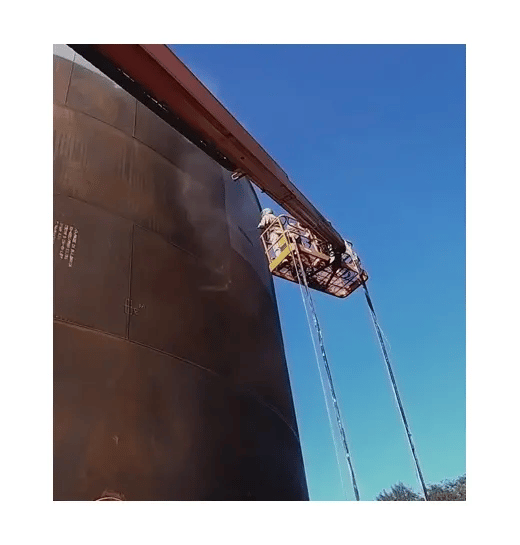

A week's work in one day: 15% overall lower project costs with GMA NewSteel™

By switching from waste slag to a premium garnet abrasive, Apache increased productivity by 71%, saved 15% in project costs, and lowered consumption by 50% — and eliminated the health hazards associated with slags. Armed with a safer, more productive abrasive and the proper blasting technique, Apache's team is getting the job done right — and moving on to the next in record time.

Lorem ipsum dolor sit

Recommended resources

Frequently asked questions

Reducing operational costs doesn’t have to be complicated. To find out more about GMA Garnet™ and switching to garnet abrasives, visit the FAQs library.

GMA Garnet pricing is significantly higher than other abrasives. How can it possibly be cheaper for a project?

While GMA Garnet has a higher upfront cost compared to other abrasives like slag, the true cost of a project involves more than just the price per ton of abrasive. GMA Garnet’s superior efficiency, lower consumption rates, reduced labor costs, decreased equipment wear, and minimal cleanup expenses can result in overall project costs that are lower than those using cheaper abrasives. The key is that GMA Garnet delivers more value per pound used, meaning you need less material to achieve the same or better results, which can lead to substantial savings across the entire project.

Additionally, GMA offers technical support to help you optimize your blasting process. If you’re skeptical about the potential savings, GMA can arrange a demonstration or trial against your current abrasive. This will allow you to see firsthand the difference GMA Garnet can make. We also provide training for your project team to ensure they are fully equipped to maximize the benefits of using GMA Garnet. It’s important to note that there is a technical difference between blasting with garnet and slags, and our experts are available to guide your team through the transition to ensure you get the most out of the switch.

Can you provide an example of how GMA Garnet might save costs despite its higher price?

Consider a scenario where you use GMA Garnet versus a cheaper slag abrasive. With GMA Garnet, the consumption rate is much lower due to its durability and cutting efficiency. For example, if a project using slag requires 10 tons of abrasive, the same project might only need 3-4 tons of GMA Garnet. Additionally, GMA Garnet generates less dust, reducing cleanup time and costs. It also causes less wear and tear on equipment, lowering maintenance costs. When you factor in reduced labor hours due to faster blasting speeds and the ability to recycle GMA Garnet multiple times, the overall savings can outweigh the initial higher cost.

How does the TruCost Abrasive Blasting Calculator help prove that GMA Garnet can be more cost-effective?

The TruCost Abrasive Blasting Calculator is designed to give you a comprehensive comparison of project costs when using GMA Garnet versus other abrasives. It takes into account all relevant factors, including labor, material consumption, equipment costs, disposal, and project specifications. By entering your specific project details, the calculator provides a clear and accurate cost analysis that often shows how GMA Garnet’s efficiency and other cost-saving benefits can result in a lower total project cost, even when starting with a higher price per ton.

What makes GMA Garnet more efficient than cheaper alternatives, and how does that impact overall costs?

GMA Garnet’s efficiency comes from its hardness, angularity, and consistent particle size, which allow it to cut through tough coatings more quickly and with fewer passes. This means you complete the job faster, reducing labor hours and equipment usage. The reduced dust generation also means less time spent on cleanup and lower risks of equipment clogging or damage, further decreasing overall costs. While the initial price of GMA Garnet may be higher, these efficiencies often lead to significant savings in the total cost of a project.

Are there any hidden costs associated with using cheaper slag abrasives that GMA Garnet helps avoid?

Yes, cheaper slag abrasives often come with hidden costs that can increase your overall project expenses. These include:

- Higher Consumption Rates: Cheaper abrasives may break down faster, requiring more material to complete the job.

- Increased Cleanup and Disposal Costs: Higher dust levels from slag abrasives lead to more extensive cleanup efforts and higher disposal costs.

- Reduced Reuse: Slag abrasives generally go into roadbase and cannot be recycled. Garnet can be reprocessed 3-5 times and reused as another abrasive in abrasive blasting or waterjet cutting.

- Greater Equipment Wear: The abrasiveness and dust from slag can cause more wear and tear on blasting equipment, leading to increased maintenance and replacement costs.

- Potential Health and Safety Risks: Slag abrasives often contain contaminants that can pose health risks to workers, possibly resulting in higher healthcare costs.

Speak to your local GMA Garnet™ expert

Lorem ipsum dolor sit

Donec consequat dolor vulputate enim rhoncus, non maximus ligula venenatis?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Nunc nec arcu eget lectus dapibus congue sed a lorem nec est scelerisque faucibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Arcu eget lectus dapibus congue?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Nunc nec arcu eget lectus dapibus congue sed a lorem nec est scelerisque faucibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.