Achieve more with less

At GMA, we help you get the best results with less product, less waste, and lower costs. Our garnet abrasives are engineered for efficiency, ensuring you maximize your output while minimizing consumption.

Cut Consumption, Boost Savings

How much abrasive do you really need to get the job done? With GMA Garnet™ blast abrasives, you can use up to 50% less to achieve the same results, leading to overall lower project costs. This reduction cuts costs not only for the abrasive itself but also for transport, disposal, labor, and equipment.

Maximize results with minimal consumption

GMA Garnet™ range of engineered garnet blends deliver high performance using less product. Thanks to its hardness, toughness, and durability, our garnet abrasives blast for longer and require fewer passes to achieve the desired result.

Our customers across various industries have seen firsthand the benefits of low consumption with GMA Garnet™. From shipyards to construction sites, our garnet is trusted to deliver consistent, high-quality results with every use.

AI generated image

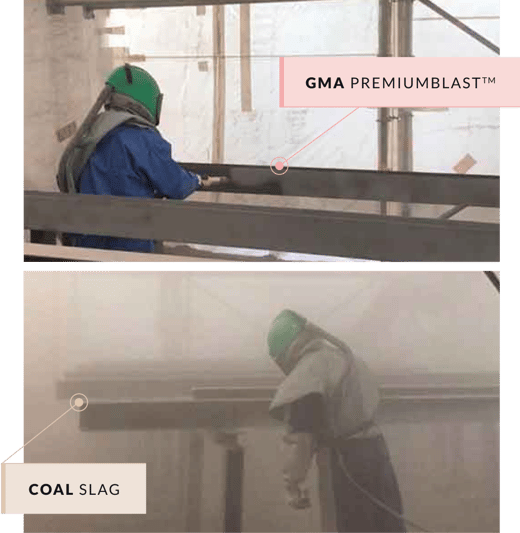

Switch from coal slag reduces abrasive consumption by 75%

A few months into using GMA Garnet™, ZÜBLIN Chimney and Refractory (ZCR) recorded a significant reduction in abrasive consumption — only 12.8 kg/m2 compared to abrasives which require 50 kg/m2. By making the switch, ZCR achieved a cleaner and safer working environment for its workers while removing thick coatings with lower abrasive consumption.

Efficient blasting: Achieve more with less garnet

GMA Garnet™ is specifically designed to reduce abrasive consumption in blasting operations. Its sharp, angular grains deliver faster, more efficient surface preparation, allowing you to use significantly less material across a project compared to slag. With the need to redo and refill reduced, so is operator downtime, avoiding deadline and budget blowouts.

Cut consumption and reduce the costs

With GMA Garnet™, you’ll experience significant cost savings. Our abrasives are not only more efficient but also more economical in the long run. By reducing the amount of abrasive needed for each job, you’ll lower your material costs and drastically reduce spend on waste disposal.

See how much you could save with GMA’s TruCost Calculator.

Lorem ipsum dolor sit

Recommended resources

Frequently asked questions

Find out more about the differences in consumption rates between abrasives. To browse answers to all frequently asked questions, visit the FAQs library.

What factors affect abrasive consumption rates, and how does the hardness of GMA Garnet impact its consumption compared to slag abrasives?

Several factors influence abrasive consumption rates, including the type and hardness of the abrasive, blasting pressure, the distance between the nozzle and the surface, surface conditions, and the presence of coatings or contaminants. GMA Garnet, with a hardness of 7.5-8.0 on the Mohs scale, is significantly more durable than slag abrasives. This increased durability means GMA Garnet breaks down less during use, resulting in lower consumption rates. In contrast, slag abrasives break down more quickly, requiring more frequent replenishment and leading to higher overall consumption.

Can GMA Garnet be reused to reduce consumption?

Yes, GMA Garnet is highly recyclable and can be reused multiple times without significant performance loss. This ability to recycle reduces the need for fresh abrasive, significantly lowering overall consumption rates and costs. Additionally, GMA Garnet offers a Return Program, where spent abrasive is collected, cleaned, and reprocessed for further use. This program ensures high recovery rates and maximizes the usability of each batch of abrasive, further driving down consumption and associated costs. Slag abrasives, however, are less recyclable due to their rapid breakdown and higher dust generation, leading to higher consumption and disposal costs.

How does GMA Garnet’s lower consumption rate translate to overall cost savings?

GMA Garnet’s lower consumption rate leads to substantial cost savings across several areas. Firstly, less abrasive is used per project, resulting in direct material cost savings. Additionally, the reduced need for frequent abrasive replenishment minimizes downtime, lowering labor costs and increasing operational efficiency. The high recyclability of GMA Garnet further reduces material costs as it can be reused multiple times.

Lower dust generation improves visibility and safety, reducing cleanup time and costs. Additionally, less wear and tear on equipment due to lower dust levels and less abrasive usage translates to lower maintenance and replacement costs. These combined factors contribute to significant overall cost savings.

How does GMA Garnet consumption compare to slag abrasives?

GMA Garnet typically results in much lower consumption rates compared to slag abrasives. Due to its superior hardness and durability, GMA Garnet lasts longer and can cut through tough coatings more efficiently, meaning you need significantly less abrasive to complete a job. In many cases, using GMA Garnet can reduce abrasive consumption by up to 3 times or more compared to slag abrasives.

This reduced consumption translates into fewer material purchases, lower transportation costs, and less frequent need for abrasive replenishment, ultimately leading to substantial cost savings and improved project efficiency.

Speak to your local GMA Garnet™ expert

Lorem ipsum dolor sit

Donec consequat dolor vulputate enim rhoncus, non maximus ligula venenatis?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Nunc nec arcu eget lectus dapibus congue sed a lorem nec est scelerisque faucibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Arcu eget lectus dapibus congue?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.

Nunc nec arcu eget lectus dapibus congue sed a lorem nec est scelerisque faucibus?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec eget maximus sem. Suspendisse eget felis dolor. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam egestas justo vitae tempus interdum. Etiam blandit et lectus non malesuada.

Sed lacinia ex id risus scelerisque fermentum. Praesent tellus tortor, placerat vitae nulla a, fringilla rutrum ex. Nunc semper et risus sed convallis. Morbi sollicitudin aliquam felis a faucibus. Nullam ut dictum elit, et feugiat elit.