You’re currently viewing the Global website.

You’re currently viewing the Global website.

Would you like to switch countries or language?Product Range

Tools & Resources

Featured products

Tools & Resources

Featured products

Tools & Resources

Resources

Categories

Types

Categories

Topics

Abrasive Blasting Tech Tips English Global

The Science Behind Engineered Blends

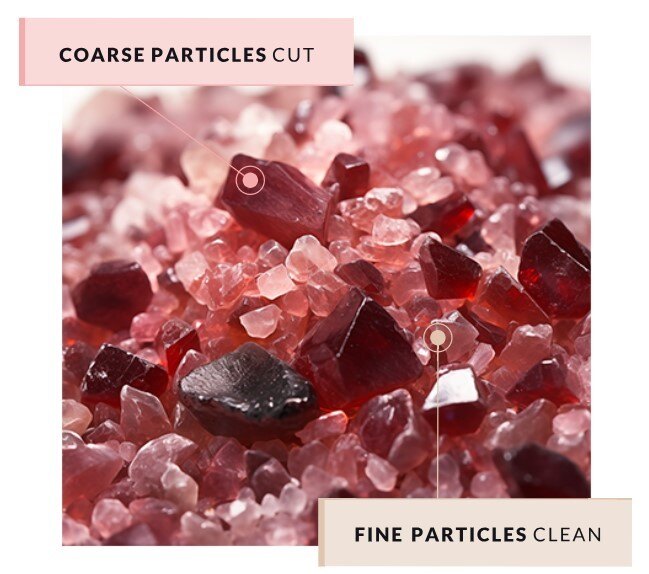

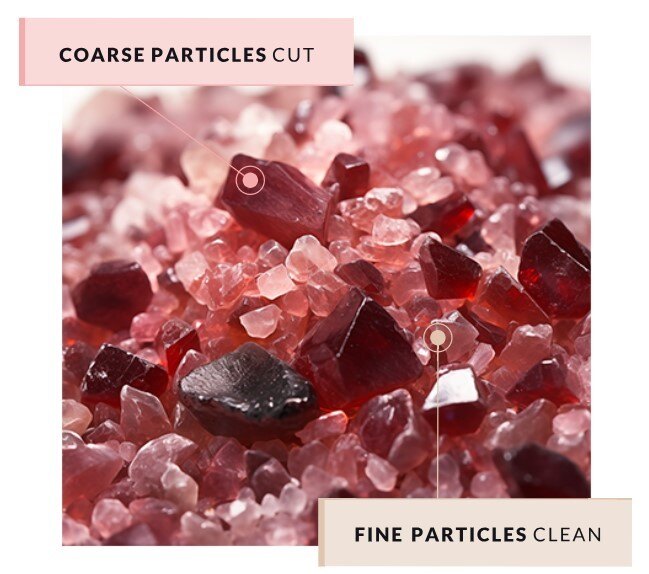

GMA’s Engineered blends represent a significant advancement in abrasive blasting technology. Combining coarse and fine particles of garnet, these blends optimize cutting and cleaning performance, setting a new standard in the industry.

Unlike traditional one-dimensional abrasives, engineered blends are formulated to leverage a wider particle distribution. This approach enhances both cutting and cleaning efficiency, making the process faster and more effective. By incorporating a mix of coarse and fine particles, GMA’s engineered blends address various surface preparation needs in a single application.

Benefits Over One-Dimensional Abrasives

Engineered blends provide increased productivity by allowing for faster cutting and cleaning, significantly reducing project timelines. This efficiency means more work can be completed in less time, saving both labor and operational costs. Additionally, the combination of coarse and fine particles results in improved surface quality, with coarse particles cutting through tough coatings and rust, and fine particles ensuring a clean surface.

The Functionality of Coarse and Fine Particles

The unique composition of GMA’s engineered blends allows for specialized functionality. Coarse particles are essential for removing the most stubborn coatings, rust, and other surface contaminants, providing the kinetic energy needed to break through these tough layers efficiently. After the coarse particles have done their job, the fine particles enhance surface cleanliness and create a better anchor profile, ensuring the surface is optimally prepared for coating adhesion.

Productivity and Surface Quality

GMA Engineered Blends are optimized for blasting performance, providing a cleaner surface that enhances coating adhesion and integrity. This leads to fewer secondary cleaning requirements and better overall project outcomes. By minimizing the need for additional cleaning steps, these blends help maintain project schedules and improve the longevity of applied coatings.

To explore the full range of GMA’s engineered blends and discover how they can improve your blasting projects, visit https://gmagarnet.com/en/sandblasting-media

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast

GMA SpeedBlast GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Ilmenite

Ilmenite Pyroxene

Pyroxene