You’re currently viewing the Global website.

You’re currently viewing the Global website.

Would you like to switch countries or language?Product Range

Tools & Resources

Featured products

Tools & Resources

Featured products

Tools & Resources

Resources

Categories

Types

Categories

Topics

Abrasive Blasting Tech Tips English Global

Extending Coating Life with the Right Abrasive

Using the right abrasive can significantly extend the life of coatings applied to surfaces. Cleanliness and profile depth are critical factors in coating adhesion and durability.

Importance of Clean Surfaces

A clean surface is essential for coating adhesion. Contaminants can prevent coatings from bonding properly, leading to premature failure. Studies have shown that GMA Garnet™ produces cleaner surfaces compared to typical slags. Slags often leave behind contaminants that can cause corrosion and blistering.

GMA Garnet™ is a tough natural mineral, significantly more durable than coal slags and other garnets. It is more resistant to fracturing on impact with a substrate, resulting in minimal embedment on the surface. Where slag particles embed into the surface, garnet grains tend to bounce off.

Impact of Peak Density

Peak density, or the concentration of uniform peaks per square inch, affects how well coatings adhere to surfaces. Higher peak density, achieved with GMA Garnet™, improves adhesion and reduces the amount of coating needed.

Many abrasives may be able to produce the required surface profile, but the consistency and extent of this profile across the substrate are crucial. GMA Garnet™ can generate up to 400% higher peak density than slag abrasives, leading to better coating adhesion and surface integrity.

This is achieved through a combination of the garnet's durability and tight grading on particle size, meaning more grains of the right size effectively impact the surface, producing the required result. Less fracturing of grains on impact and fewer over or undersized grains ensure a consistent surface profile.

The Role of Uniform Surface Profile

The uniformity of the surface profile plays a major role in coating adhesion and lifespan. A more consistent surface profile with fewer extremely high or low peaks and valleys requires less primer to achieve coating specification, reducing labour and material costs while allowing the coatings to perform optimally.

Consistent sizing and systematic QA & QC testing of GMA Garnet™ blasting abrasives over 12 areas of performance ensure consistent results from batch to batch. This consistency prevents larger or smaller particles from causing an inconsistent surface profile, leading to better overall coating performance.

Discover more on how GMA improved peak density and coating adhesion

- Case Study 1: Reduced surface contamination leads to better coating adhesion and longer-lasting protection. (LINK)

- Case Study 2: GMA Garnet™ produces up to four times higher peak density compared to slags, enhancing coating life and reducing maintenance costs. (LINK)

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast

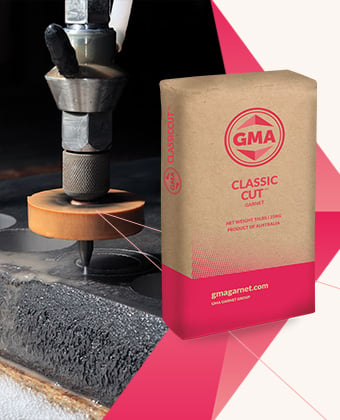

GMA SpeedBlast GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Ilmenite

Ilmenite Pyroxene

Pyroxene